-

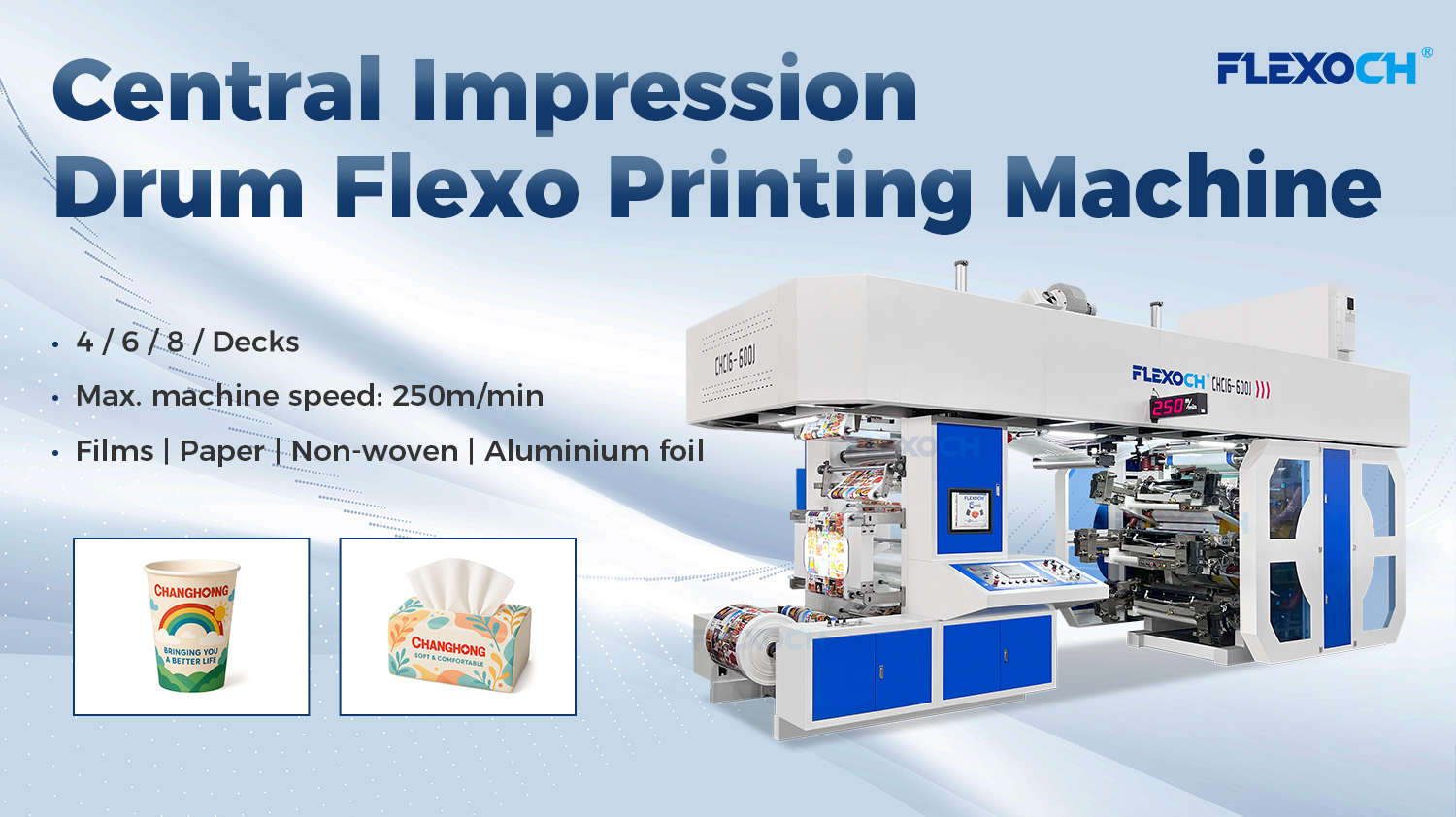

SOLUTION FOR CENTRAL IMPRESSION DRUM FLEXO PRINTING MACHINE TO ACHIEVE HIGH-SPEED PRECISION PACKAGING PRINTING

In the field of flexible packaging and label printing, central impression (CI) flexo printing machine have become indispensable equipment for large-scale production due to their stable and efficient performance. They are particularly adept at handling flexible web materi...Read more -

THE REVOLUTIONARY ADVANTAGES AND PRINCIPLES OF HIGH SPEED FULL SERVO CI GEARLESS FLEXO PRINTING PRESS

Amidst the rapid growth of the packaging and printing industry, companies are increasingly demanding higher production efficiency, printing precision, and equipment flexibility. Gearless flexo printing press have long played a vital role in the market. However, with incr...Read more -

STACK FLEXO PRESS /FLEXOGRAPHIC PRINTING MACHINE MANUFACTURER EFFICIENT AND FLEXIBLE 2 4 6 8 MULTI COLOR PRINTING SOLUTION

In the packaging and label printing industry, efficient, flexible, and stable printing equipment is a core asset for businesses. The stack flexo press with its unique structural design and exceptional multi-color printing capabilities, has become a mainstream choice in m...Read more -

THE PERFECT COMBINATION OF 2-10 MULTI COLOR PRINTING AND QUICK PLATE CHANGING IN STACK TYPE FLEXO PRINTER /FLEXOGRAPHIC PRINTING MACHINERY

In the packaging and printing industry, efficient, flexible, and high-quality printing equipment is key to enhancing a company's competitiveness. The stack type flexographic printing machinery, with its exceptional multi-color printing capabilities and quick plate-changi...Read more -

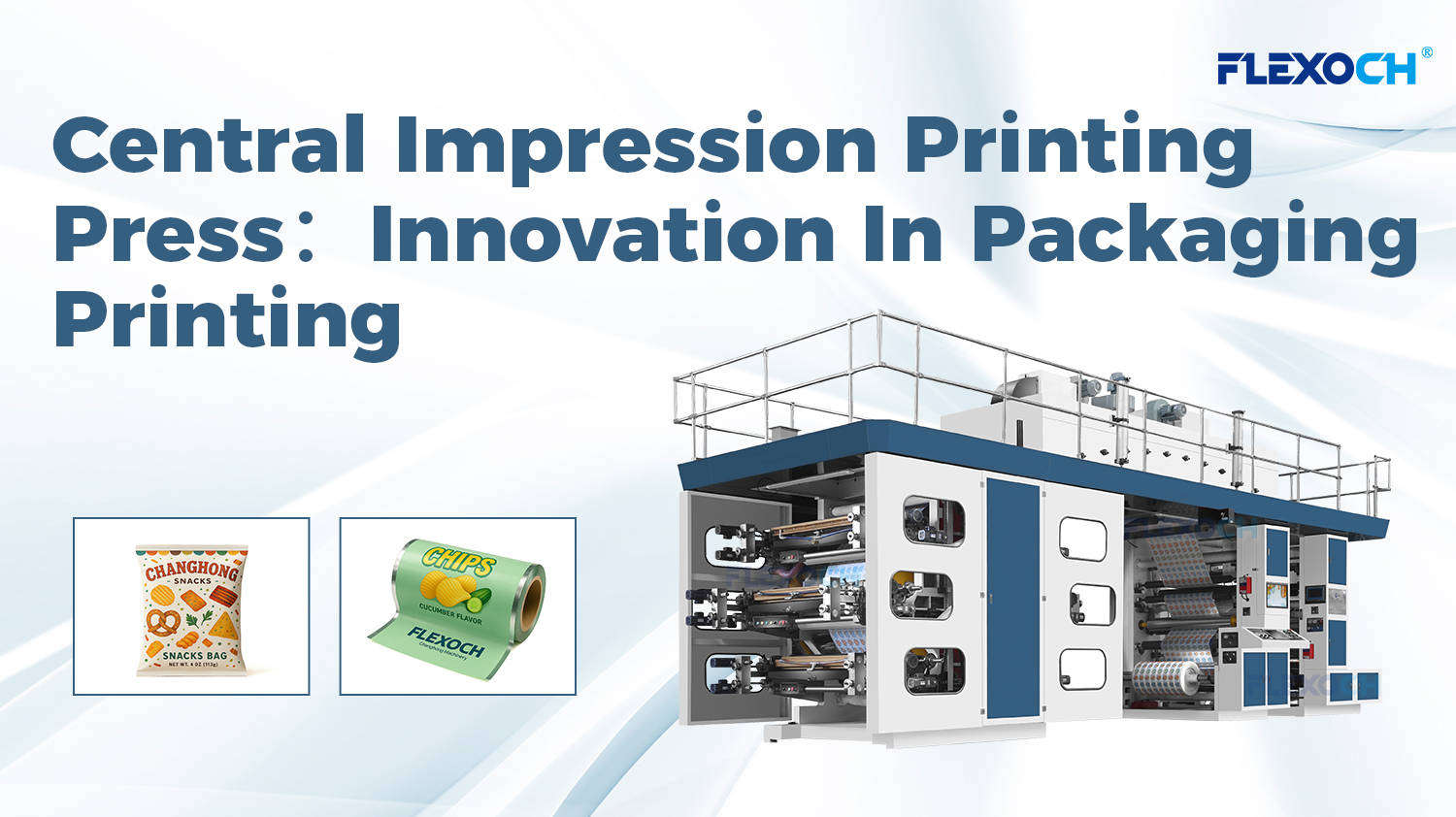

CENTRAL IMPRESSION CI FLEXOGRAPHIC PRINTING PRESS MANUFACTURERS:INNOVATIVE ADVANTAGES LEADING THE PACKAGING PRINTING MARKET

In the packaging printing industry, efficient, precise, and environmentally friendly production methods have always been the goal pursued by enterprises. With technological advancements, the Central Impression Flexo Press (ci printing machine), leveraging its unique desi...Read more -

WHY IS ROLL TO ROLL WIDE WEB 4/6/8 COLOR FLEXO PRINTING MACHINE/FLEXOGRAPHIC PRINTER FOR SALE PREFERRED FOR PLASTIC FILM OVER OTHER PRINTING METHODS?

In the packaging and printing industry, plastic films are widely used in food, daily chemicals, pharmaceuticals, and other fields due to their lightweight, durable, and highly malleable properties. Among various printing techniques, flexographic printing has become the p...Read more -

BEST CH STACK FLEXO PRESS VS CHCI CI FLEXO PRINTING MACHINE PRICE : HOW TO CHOOSE THE BEST MODEL FOR YOUR PRODUCTION NEEDS?

In today's competitive printing industry, manufacturers demand press solutions that deliver both exceptional quality and outstanding productivity for high-volume runs. Two proven technologies - the CH Stack Flexo Press and CHCI CI Flexo printing machine - have emerged as...Read more -

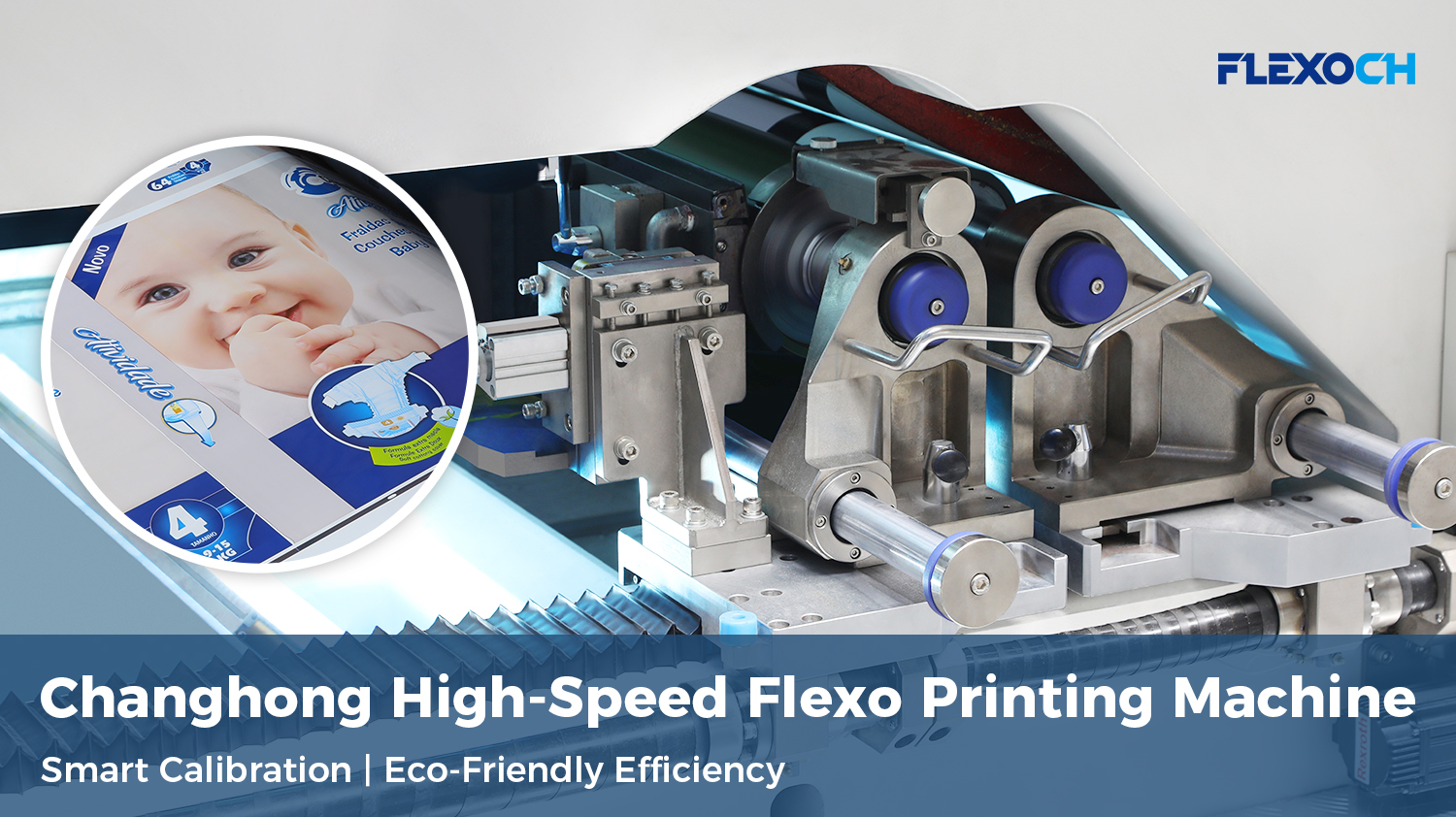

CHANGHONG HIGH-SPEED FLEXO PRINTING PRESS EFFECTIVELY IMPROVES PRINTING PRODUCTION QUALITY

In the packaging and printing industry, quality is the core of competitiveness. Changhong high-speed flexo printing press is driven by innovative technology. Through intelligent printing control and precise mechanical design, it ensures that every pattern is clear and sh...Read more -

HOW TO CHOOSE A FLEXOGRAPHIC PRINTING MACHINE SUITABLE FOR DIFFERENT MATERIALS?

Flexographic printing machine are popular for their flexibility, efficiency and environmental friendliness, but choosing a "tailor-made" flexographic printing machine is not easy. This requires comprehensive consideration of material properties, printing technology, equi...Read more