In the packaging and printing industry, efficiency and versatility are key to winning market competition. When selecting a printing solution for your products, a core question often arises: stack type flexo printing presses efficiently handle two-sided (double-sided) printing?

The answer is yes, but it requires a deeper understanding of the implementation methods and unique advantages.

The Secret Behind Double-Sided Printing with Stack-Type Structure

Unlike central impression ci flexo printing press, which feature one large central impression cylinder, stack type flexo printing machine have independent printing units stacked on top of each other. This modular design is the foundation for achieving double-sided printing. There are two primary methods to accomplish this:

1.Turn-Bar Method: This is the most commonly used and classic approach. During the assembly of the printing press, a device called a "turn-bar" is installed between specific printing units. After the substrate (such as paper or film) completes printing on one side, it passes through this turn-bar. The turn-bar cleverly guides the substrate, swapping its top and bottom surfaces while simultaneously aligning the front and back sides. The substrate then proceeds to subsequent printing units for printing on the reverse side.

2.Dual-Side Configuration Method: For high-end stack type flexo printing machine, double-sided printing is typically achieved through built-in precision turn-bar mechanisms. The substrate first passes through one set of printing units to complete all colors on the front side. It then goes through a compact turning station, where the web is automatically flipped 180 degrees before entering another pre-configured set of printing units to complete printing on the reverse side.

● Machine Details

Advantages of Choosing stack type flexo printing machine for Double-Sided Printing.

1.Unparalleled Flexibility: You have the freedom to choose how many colors to print on each side of the substrate. For example, the front side can feature a complex 8-color design, while the reverse side may only require 1-2 colors for explanatory text or barcodes.

2.Excellent Registration Accuracy: Stack type flexographic printing press are equipped with precise tension control and registration systems, ensuring accurate pattern alignment on both sides even after passing through the turn-bar. This meets the demands of high-end packaging.

3.Strong Substrate Adaptability: Whether it’s thin facial paper, self-adhesive labels, various plastic films, or non-woven fabrics, the stack-type design handles these materials with ease, preventing issues during double-sided printing due to material characteristics.

4.Production Efficiency and Cost-Effectiveness: Completing double-sided printing in a single pass eliminates the hassle of secondary registration and potential waste, significantly improving production efficiency and reducing overall production costs.

● Video Introduction

Conclusion

Thanks to the inherent advantages of its modular design, stack flexo printing machine not only achieve double-sided printing but also make it an efficient, flexible, and economical process. If you are looking for printing equipment that can effortlessly handle double-sided printing while balancing efficiency and quality, it are undoubtedly a trustworthy and excellent choice.

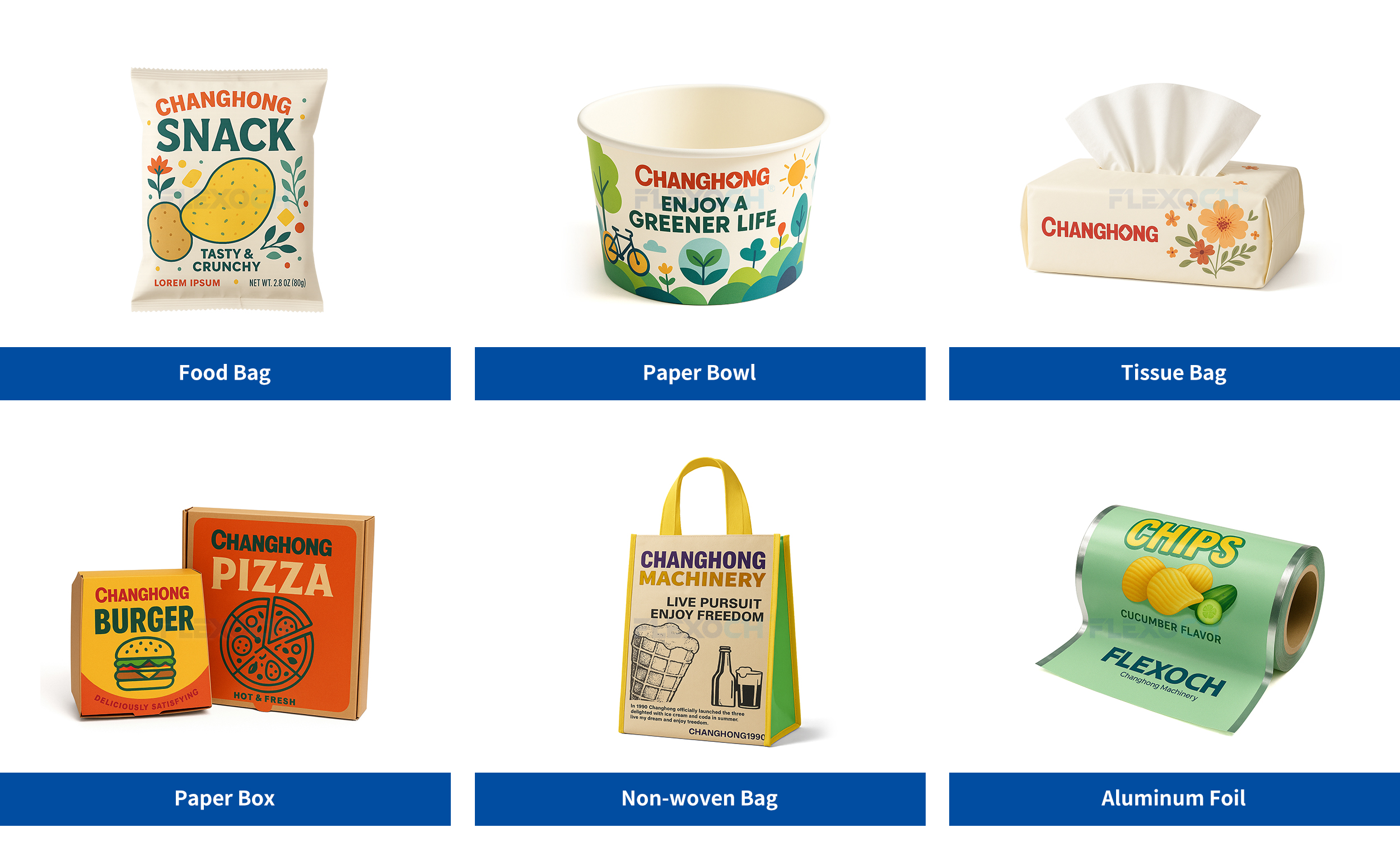

Application Scenarios

● Printing Sample

Post time: Sep-09-2025