Amidst the rapid growth of the packaging and printing industry, companies are increasingly demanding higher production efficiency, printing precision, and equipment flexibility. Gearless flexo printing press have long played a vital role in the market. However, with increasingly stringent demands for ultra-high screen printing, precise registration, and fast job changeovers, the limitations of traditional mechanical structures are becoming increasingly apparent. In response to this trend, gearless flexographic printing presses, with their innovative technological concepts, are becoming a new driving force for high-quality printing.

Core Advantages: Why Choose a Gearless Flexographic Press?

● Excellent Print Quality and Precise Registration: Gearless flexo printing press completely eliminate the "gear marks" associated with traditional gear drives, achieving more uniform dot reproduction and smoother print results. Independent servo motors drive each print unit, achieving unparalleled registration accuracy, ensuring clear and stable reproduction of both continuous images and fine text.

● Flexible and Efficient Printing: Equipped with one-touch pre-registration and remote plate adjustment, the gearless flexo printing machine significantly reduces makeready time. When changing the plate cylinder, there's no need to replace gears; simply input the circumference parameters for automatic adjustment, enhancing production flexibility.

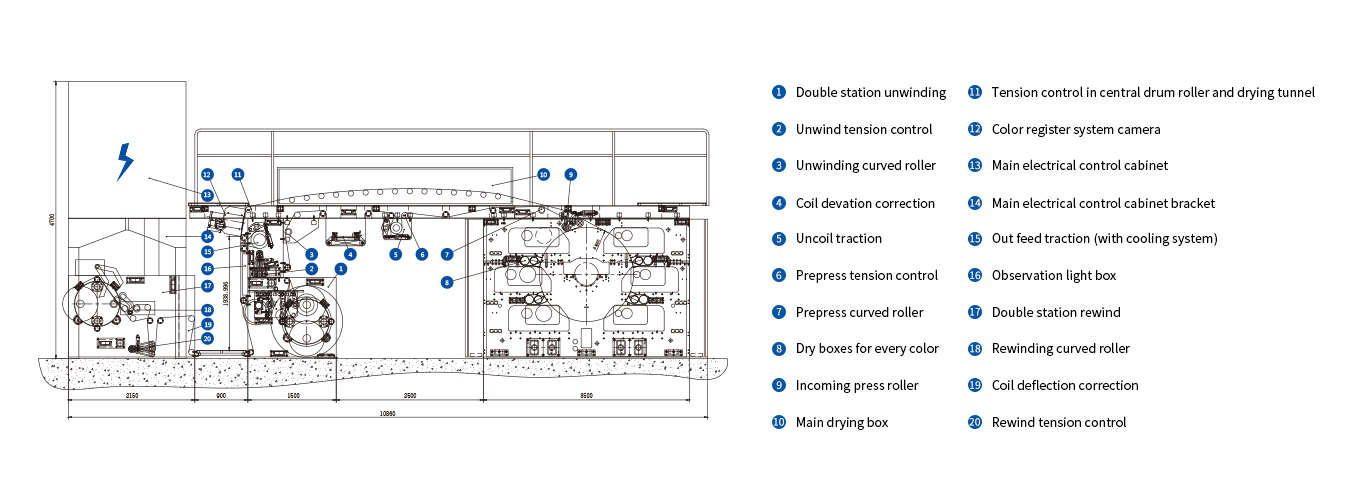

Plastic Gearless Flexo Printing Press Material Feeding Diagram

● Higher Operational Efficiency and Lower Maintenance: The significantly simplified mechanical transmission structure eliminates downtime caused by gear wear and poor lubrication. The equipment also offers smoother operation, lower noise levels, and a longer service life, effectively reducing long-term maintenance and operating costs.

● Wide Material Compatibility: The servo system's precise tension control and gentle transmission ensure stable processing of a wide range of substrates, enabling efficient printing on everything from ultra-thin specialty films to heavyweight cardboard, minimizing material loss. This makes it particularly suitable for high-precision printing applications such as food packaging, pharmaceutical packaging, and labels.

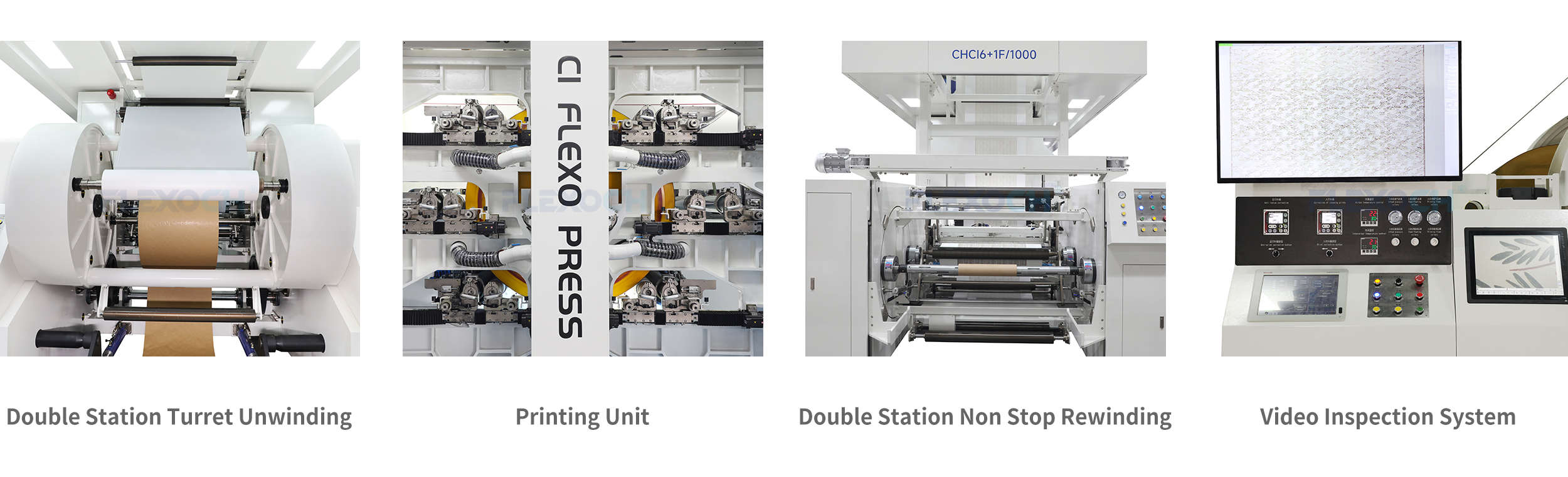

● Machine Details

How it Works: How Does Technology Achieve Excellence?

The core of the gearless flexo printing press lies in its decentralized, independent drive architecture. The plate cylinder and anilox roller in each printing unit are independently driven by high-precision AC servo motors, acting like a precision army operating under unified command. The system generates a high-speed virtual electronic spindle signal, and all drives synchronously track its phase and speed, achieving absolute synchronization of hundreds of moving axes at high speeds and unparalleled precision in "electronic gear meshing." This is powered by intelligent closed-loop control: Each motor receives real-time feedback in milliseconds via a high-resolution encoder, allowing the control system to dynamically adjust, ensuring exceptionally stable tension and registration accuracy despite acceleration, deceleration, and material changes.

● Video Introduction

In short, our gearless ci flexo printing machines is more than just a piece of equipment; it's a future-oriented intelligent printing solution. It seamlessly blends mechanical precision with electronic intelligence, freeing printers from complex mechanical adjustments and allowing them to focus more on creativity and color. Choosing us means choosing higher quality, higher efficiency, and lower overall costs. Embrace gearless technology and let us print the future together!

● Printing Sample

Post time: Aug-25-2025