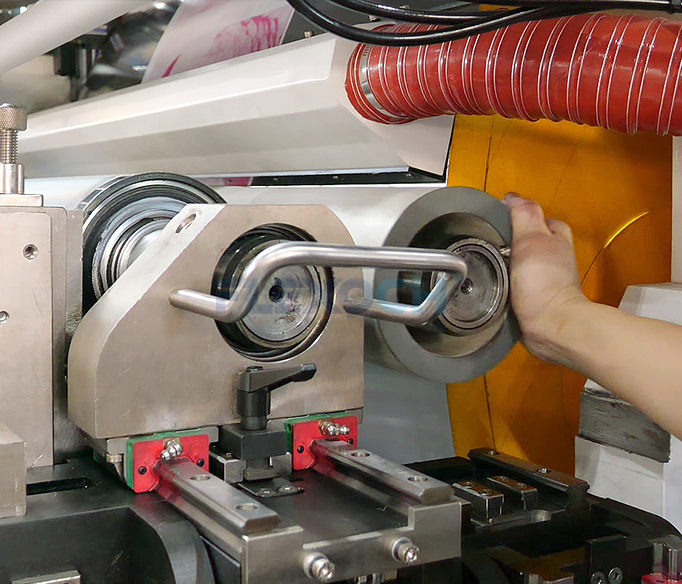

1.This CI flexo press features a sleeve change system for quick swapping of printing plates and anilox rolls. This reduces job-change downtime, lowers equipment costs, and simplifies operations.

2.It features high-performance servo unwinding/rewinding and a precision tension control algorithm. The system maintains stable web tension during acceleration, operation, and deceleration, preventing start/stop stretching or wrinkling for high-precision prints.

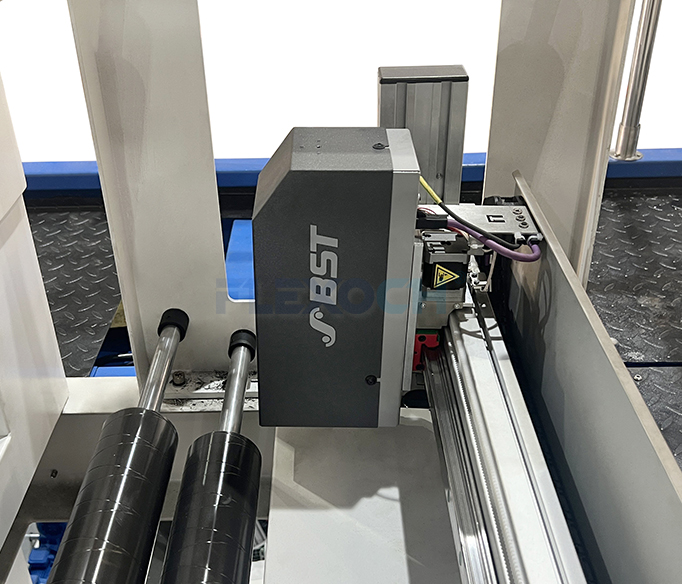

3.Built-in with the BST vision inspection system, this CI flexographic printing machine monitors print quality in real time. It automatically spots defects and adjusts registration, reducing reliance on operator experience and minimizing material waste.

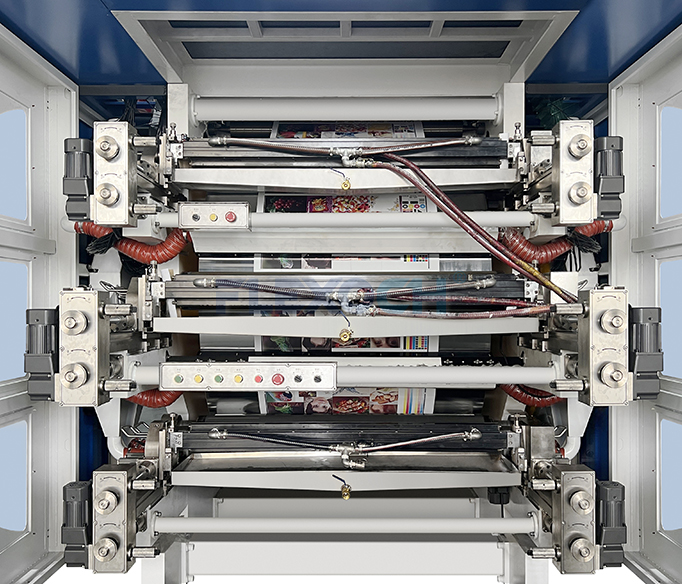

4.All printing units are precisely arranged around a single central impression cylinder. This stabilizes substrate tension, prevents printing misalignment, and ensures ultra-precise multi-color registration.