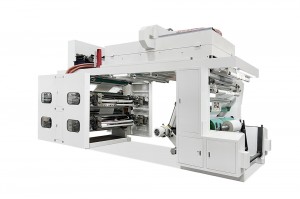

1.Precision: Central impression (CI) enhances the precision of PP woven bag ci flexo printing press. Each color unit is positioned around the main drum to keep tension steady and printing precise. This setup helps to avoid errors caused by material stretching, while also enhancing the machine’s operating speed and improving accuracy.

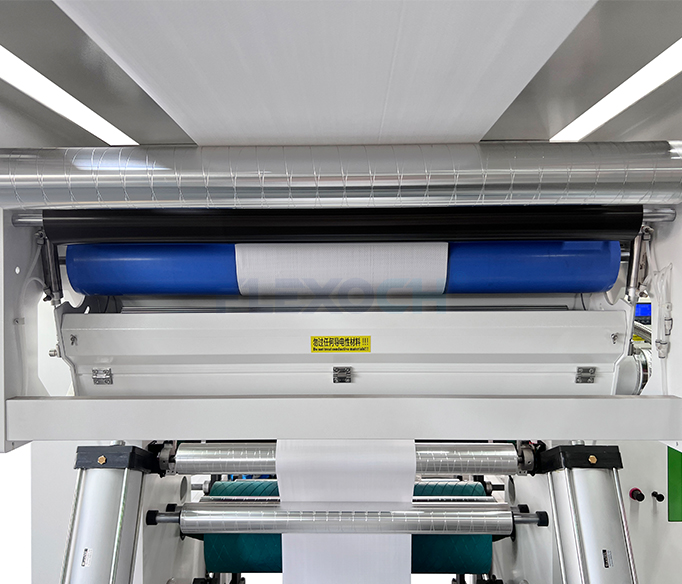

2.Clear Printing: Due to the adoption of the corona treatment system, the PP woven bag ci flexo printing press performs surface treatment on the product before printing, in order to enhance the adhesion of the ink and the color performance. This process can minimize the ink bleeding phenomenon and prevent fading, while ensuring that the printed final product has a clear, sharp and long-lasting effect.

3.Rich color: Due to the adoption of a four color ci flexographic printing machine for PP woven, it can present a wider range of colors and achieve a clear and consistent printing effect.

4.Efficiency and stabilization: By using the surface winding method, the winding tension of the central drum flexo printing machine is uniform, and the rolls are smooth and aesthetically pleasing With an intelligent control system, it can adjust tension automatically. This setup makes production more efficient and cuts down on manual work.