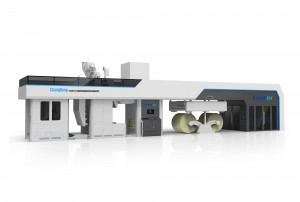

Double station unwinding

Full servo Printing system

Pre registration function (Automatic Registration)

Production menu memory function

Start up and shut down automatic clutch pressure function

Automatic pressure adjustment function in the process of printing speed up

Chamber doctor blade quantitative ink supply system

temperature control and centralized drying after printing

EPC before printing

It has cooling function after printing

Double station winding.