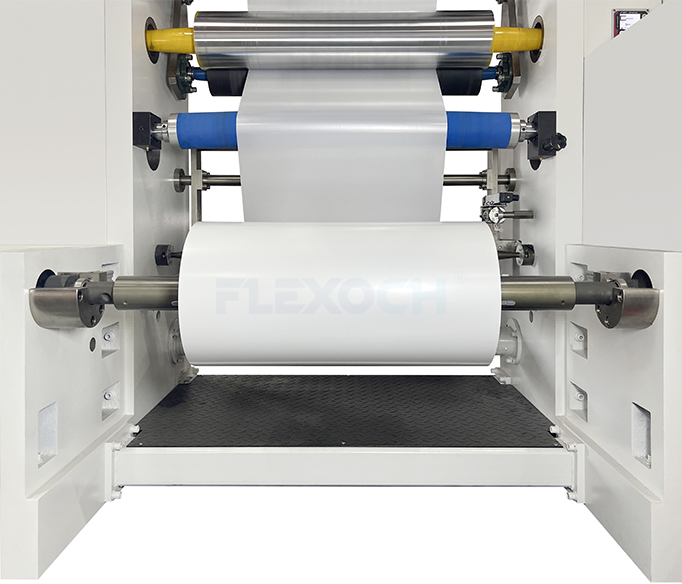

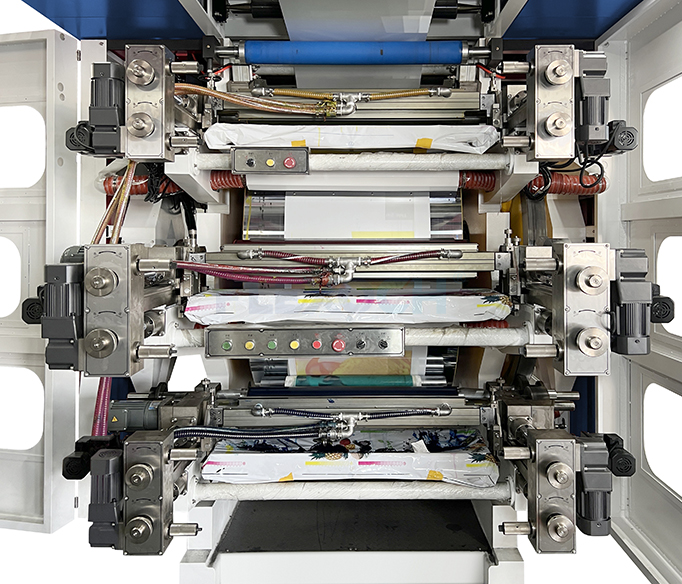

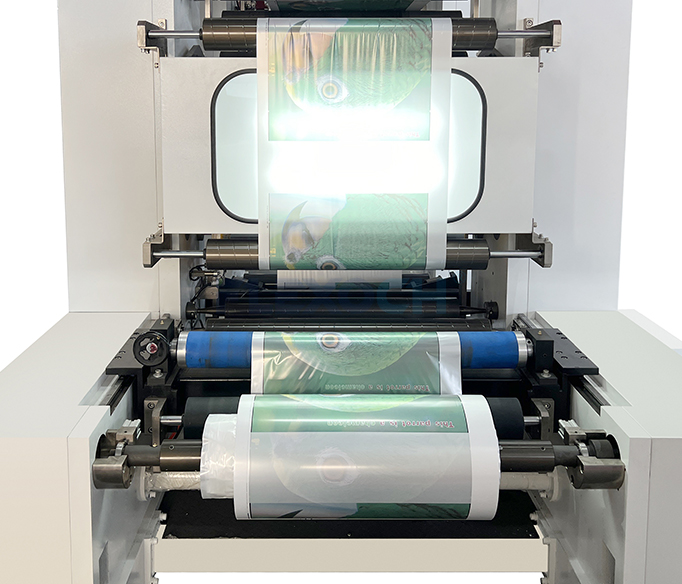

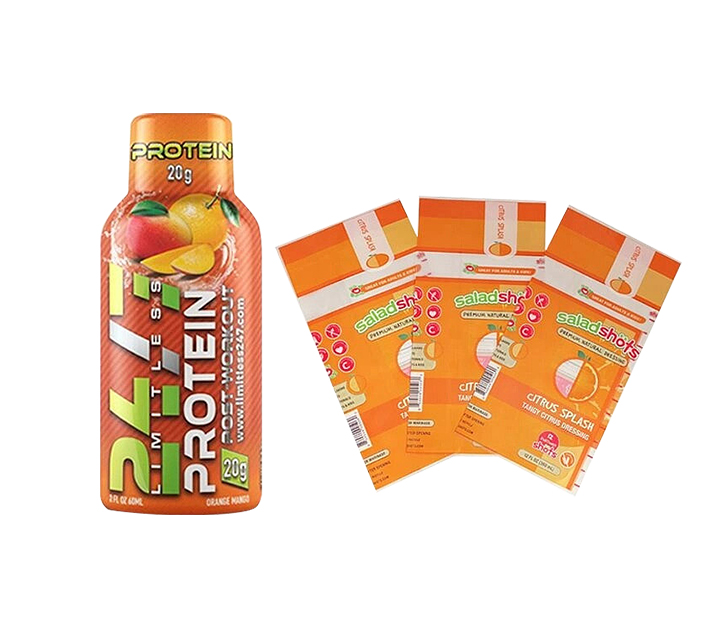

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for Trending Products Flexo Printing Machine Petal Type for plastic films BOPP/LDPE/CPP/OPP, Now we’ve set up steady and long small business interactions with consumers from North America, Western Europe, Africa, South America, far more than 60 countries and regions.

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for , So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we give, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We’re confident that we are gonna share mutual achievement and create strong co-operation relations with our companions in this marketplace. We’re searching forward for your inquiries.

|

model

|

CHCI6-600E-S

|

CHCI6-800E-S

|

CHCI6-1000E-S

|

CHCI6-1200E-S

|

|

Max.Web Width

|

700mm

|

900mm

|

1100mm

|

1300mm

|

|

Max.Printing Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max.Machine Speed

|

350m/min

|

|

Max. Printing Speed

|

300m/min

|

|

Max.Unwind/Rewind Dia.

|

Φ800mm /Φ1000mm/Φ1200mm |

|

Drive Type

|

Central drum with Gear drive |

| Photopolymer Plate |

To be specified |

|

Ink

|

Water base ink olvent ink |

|

Printing Length (repeat)

|

350mm-900mm |

|

Range Of Substrates

|

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

|

Electrical Supply

|

Voltage 380V.50 HZ.3PH or to be specified |

Well-run equipment, professional sales team, and better after-sales services; We are also a unified big family, everyone stick to the company value “unification, dedication, tolerance” for Trending Products Flexo Paper Cup Printing Machine Petal Type, Now we’ve set up steady and long small business interactions with consumers from North America, Western Europe, Africa, South America, far more than 60 countries and regions.

Trending Products Flexo Printing Machine and Flexographic Printing Machine, So that you can utilize the resource from the expanding info in international trade, we welcome shoppers from everywhere on-line and offline. In spite of the good quality solutions we give, effective and satisfying consultation service is supplied by our specialist after-sale service team. Product lists and detailed parameters and any other info weil be sent to you timely for your inquiries. So you should make contact with us by sending us emails or call us if you have any questions about our corporation. ou may also get our address info from our web page and come to our company to get a field survey of our merchandise. We’re confident that we are gonna share mutual achievement and create strong co-operation relations with our companions in this marketplace. We’re searching forward for your inquiries.