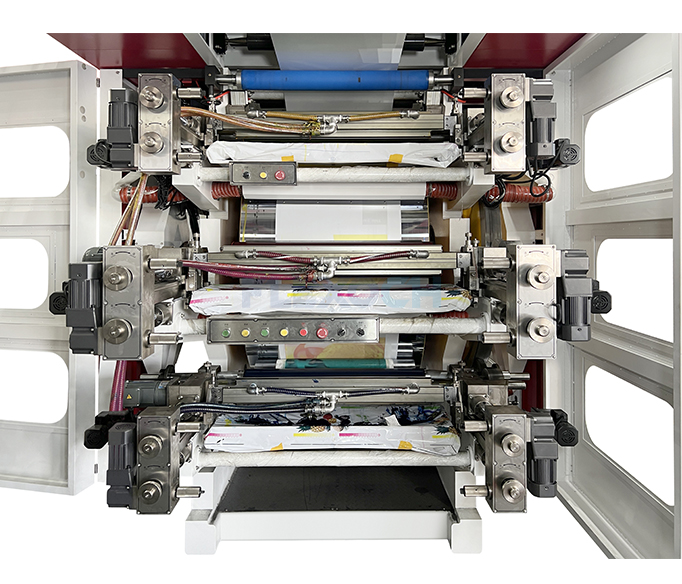

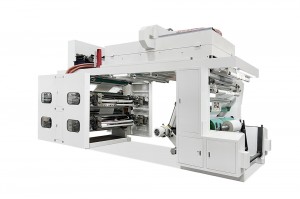

1.The ci flexo printing press adopts central impression roller technology, is compatible with water-based/UV-LED zero-solvent inks, and cooperates with linear encoding feedback and HMI intelligent control to ensure high-definition pattern restoration and food-grade safety standards.

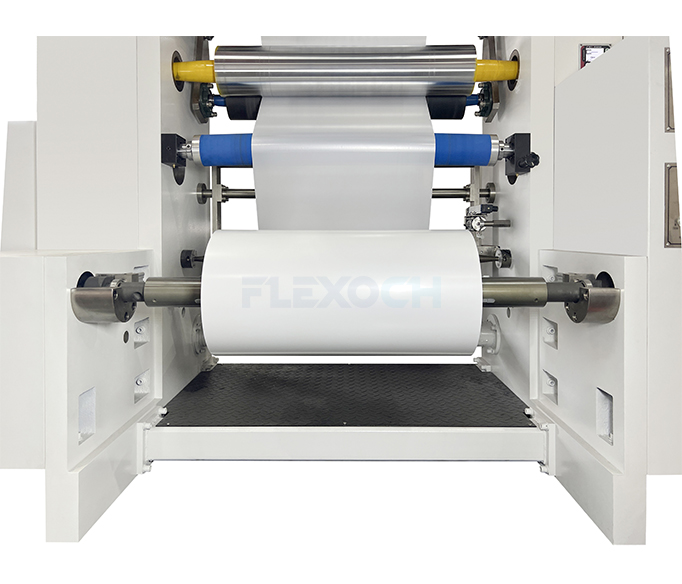

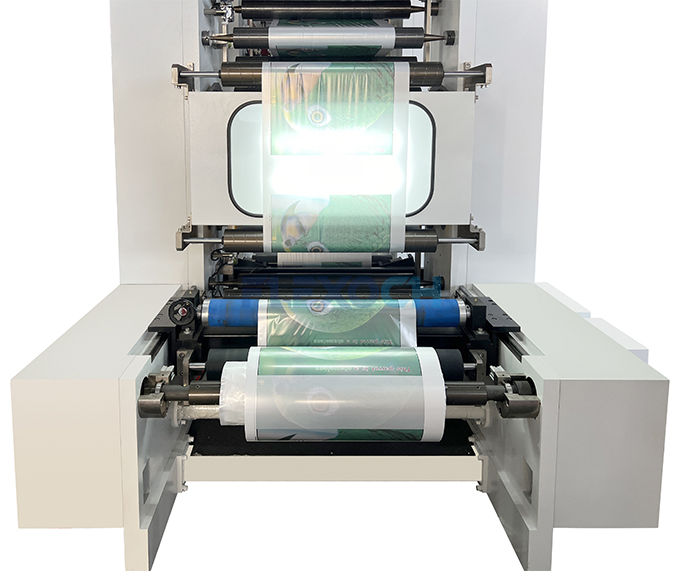

2.The ci flexo printing press has the characteristics of high-speed production and multi-functional modules. The precision traction roller system supports high-speed and stable operation, and integrates the embossing roller module to simultaneously complete printing, embossing texture or anti-counterfeiting processing, and is suitable for 600-1200mm wide PE film.

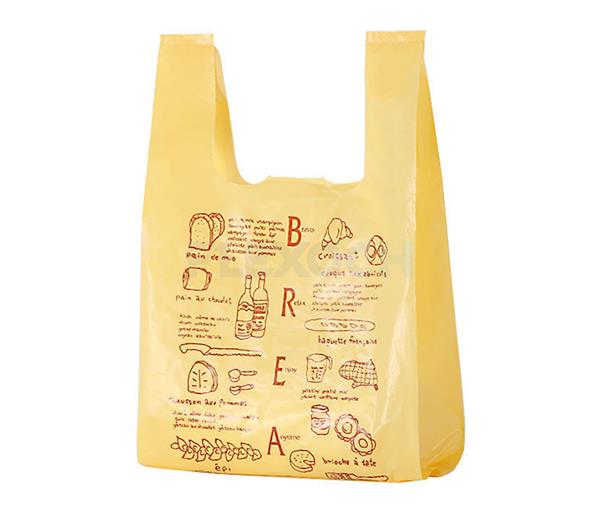

3.Flexographic printing machine has efficient application and market value. The modular design realizes fast order change, supports the development of high-value-added packaging, and helps enterprises reduce costs, increase efficiency and differentiate competition.