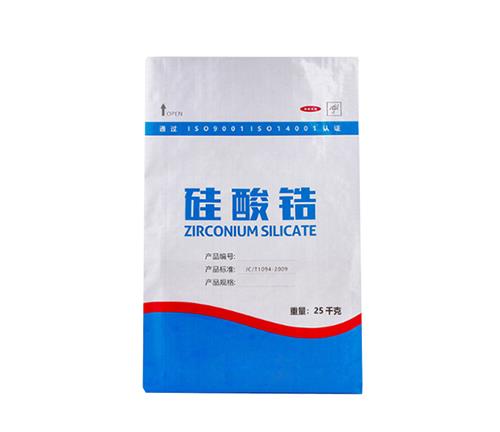

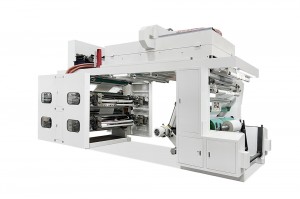

1.Stack type PP woven bag flexographic printing machine is a highly advanced and efficient printing technology that is widely used in the packaging industry. This machine is designed to print high-quality and colorful designs on PP woven bags, which are commonly used for packaging various products such as grains, flour, fertilizer, and cement.

2.One of the biggest advantages of the stack type PP woven bag flexographic printing machine is its ability to print high-resolution images with sharp colors. This technology employs advanced printing techniques that result in precise and consistent prints, ensuring that each PP woven bag looks its best.

3.Another great advantage of this machine is its efficiency and speed. With the ability to print at high speeds and handle large volumes of bags, the stack type PP woven bag flexographic printing machine is an ideal choice for manufacturers looking to streamline their production processes and save time and money.