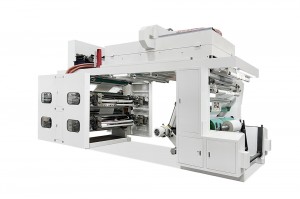

All we do is usually linked with our tenet ” Shopper first, Rely on very first, devoting around the food packaging and environmental safety for PriceList for 4 6 8 Color High-Speed Woven/BOPP Plastic Bag Paper Bag stack Flexo Printing Machine, Together with our endeavours, our products and solutions have won the trust of buyers and been quite salable the two here and abroad.

All we do is usually linked with our tenet ” Shopper first, Rely on very first, devoting around the food packaging and environmental safety for , We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.

|

Model

|

CH8-600S-S

|

CH8-800S-S

|

CH8-1000S-S

|

CH8-1200S-S

|

|

Max. Web Width

|

650mm

|

850mm

|

1050mm

|

1250mm

|

|

Max. Printing Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max. Machine Speed

|

200m/min

|

|

Max. Printing Speed

|

150m/min

|

|

Max. Unwind/Rewind Dia.

|

Φ800mm

|

|

Drive Type

|

Servo drive

|

|

Photopolymer Plate

|

To be specified

|

|

Ink

|

Water base ink or solvent ink

|

|

Printing Length (repeat)

|

350mm-1000mm

|

|

Range Of Substrates

|

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon,

|

|

Electrical Supply

|

Voltage 380V. 50 HZ.3PH or to be specified

|

All we do is usually linked with our tenet ” Shopper first, Rely on very first, devoting around the food packaging and environmental safety for PriceList for 4 6 8 Color High-Speed Woven/BOPP Plastic Bag Paper Bag stack Flexo Printing Machine, Together with our endeavours, our products and solutions have won the trust of buyers and been quite salable the two here and abroad.

PriceList for stack type Flexo Printing Machine and Flexographic Printing Machine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.