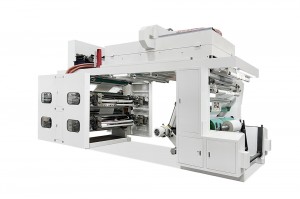

1. This ci flexographic printing press features a continuous, double station non-stop system, allowing the main printing unit to continue operating while changing printing materials or performing preparatory work. This completely eliminates the time wasted stopping for material changes associated with traditional equipment, significantly shortening work intervals and significantly improving overall production efficiency.

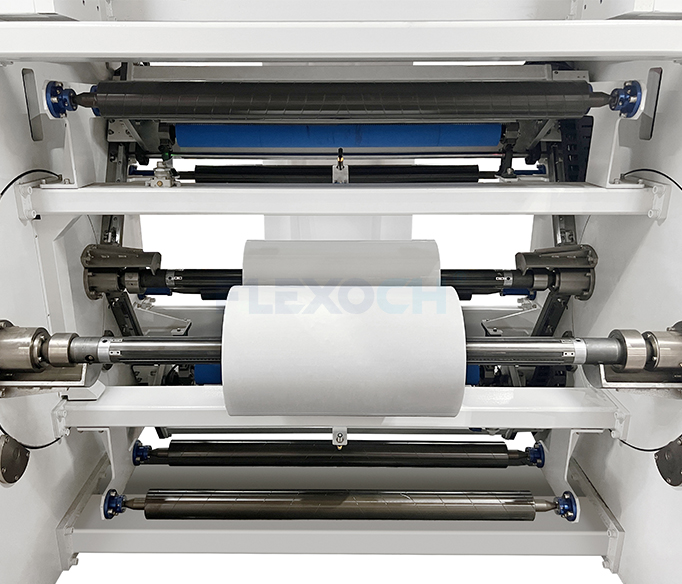

2. The double station system not only ensures continuous production but also achieves near-zero material waste during splicing. Precise pre-registration and automatic splicing eliminate significant material loss during each start-up and shutdown, directly reducing production costs .

3. The core central impression (CI) cylinder design of this flexographic printing machine guarantees high-quality printing. All printing units are arranged around a massive, precision temperature-controlled central cylinder. The substrate closely adheres to the cylinder surface during printing, ensuring extremely high registration accuracy and unparalleled consistency throughout the production process.

4. Additionally, this ci flexo printing machine is optimized for the printing characteristics of plastic substrates. It effectively addresses issues like stretching and deformation of plastic films, ensuring exceptional registration accuracy and stable color reproduction even at high speeds.