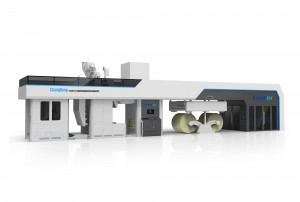

Gaining purchaser fulfillment is our company’s purpose without end. We will make terrific initiatives to acquire new and top-quality solutions, meet up with your exclusive specifications and provide you with pre-sale, on-sale and after-sale providers for ODM Manufacturer Flexographic Printer Machine Roll to Roll for Plastic Bags Gearless CI Printing Machine, Our mission is usually to enable you to build long-lasting associations with your shoppers by the power of marketing products and solutions.

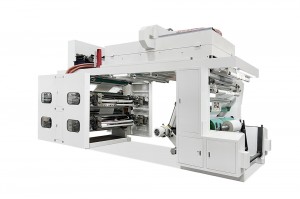

Gaining purchaser fulfillment is our company’s purpose without end. We will make terrific initiatives to acquire new and top-quality solutions, meet up with your exclusive specifications and provide you with pre-sale, on-sale and after-sale providers for Central Impression flexo printing machine and Ci Type Flexo Printing Machine, Many years of work experience, we’ve got realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down all those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

| Model |

CHCI8-600F-S |

CHCI8-800F-S |

CHCI8-1000F-S |

CHCI8-1200F-S |

| Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

| Max. Printing Width |

600mm |

800mm |

1000mm |

1200mm |

| Max. Machine Speed |

500m/min |

| Max. Printing Speed |

450m/min |

| Max. Unwind/Rewind Dia. |

Φ800mm/Φ1200mm |

| Drive Type |

Gearless full servo drive |

| Photopolymer Plate |

To be specified |

| Ink |

Water base ink or solvent ink |

| Printing Length (repeat) |

400mm-800mm |

| Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, Breathable Film |

| Electrical Supply |

Voltage 380V. 50 HZ.3PH or to be specified |

Gaining purchaser fulfillment is our company’s purpose without end. We will make terrific initiatives to acquire new and top-quality solutions, meet up with your exclusive specifications and provide you with pre-sale, on-sale and after-sale providers for ODM Manufacturer Flexographic Printer Machine Roll to Roll for Plastic Bags Gearless CI Printing Machine, Our mission is usually to enable you to build long-lasting associations with your shoppers by the power of marketing products and solutions.

ODM Manufacturer Central Impression flexo printing machine and Ci Type Flexo Printing Machine, Many years of work experience, we’ve got realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down all those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

.jpg)