In the field of packaging printing, 4/6/8-color flexographic printing machines are core equipment for achieving exquisite multi-color printing. The "central drum design" (also known as the Central Impression, or CI, structure), by virtue of its precise adaptation to the multi-color printing needs of such flexographic machines, has become a mainstream technical solution.

As a structural design specifically developed for 4/6/8-color flexographic printing, the Ci Type Flexo Printing Machine fundamentally aligns with the core requirements of multi-color printing. It demonstrates irreplaceable unique advantages in three key dimensions: precision control of multi-color pattern overlay, efficiency improvement in continuous production, and compatibility with different substrates—providing core support for high-quality, stable production in multi-color flexographic printing.

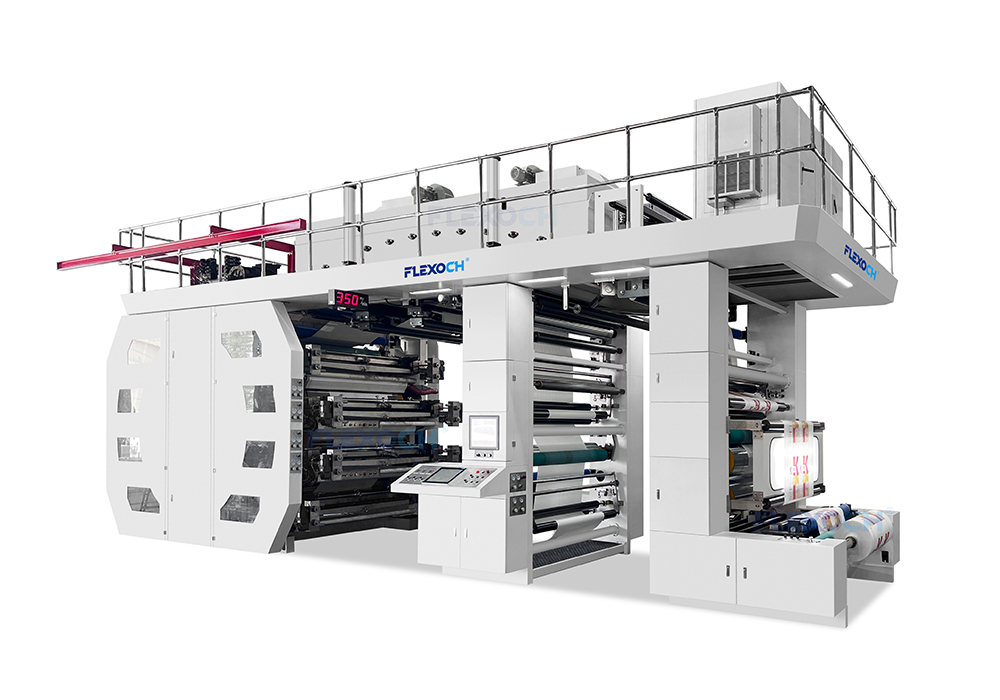

Central Impression Ci Flexo Printing Press 8 Colour

Corona Treatment Ci Flexo Printing Press 4 colour

I. Clear Positioning: Core Application Scenarios of the Central Drum Structure

The structural design of printing equipment is essentially a precise response to specific production needs. For 4/6/8-color flexo printing, where multi-color synchronization and high precision are core requirements, the design logic of the central drum structure achieves targeted matching.

From the perspective of core structure, the Ci Type Flexo Printing Machine centers on a single large-diameter, high-rigidity central impression cylinder, around which 4 to 8 color stations are arranged in a circular pattern. During the printing process, all color stations complete the impression process with this central drum as a unified reference. This "centralized reference" design fundamentally solves the key problem of "dispersed references leading to easy deviations" in multi-color printing, serving as the core support for realizing multi-color synchronous printing in multi-color flexographic machines.

● Machine Details

II. Four Core Features: How the Central Drum Adapts to Multi-Color Printing Needs

1. Register Accuracy: The "Stability Guarantee" for Multi-Color Synchronization

4/6/8-color printing requires precise overlay of multiple colors, and the Central impression Flexo Printing Machine ensures this precision from the source via its central drum:

● The substrate adheres closely to the fixed central drum throughout the process, reducing tension fluctuations in multi-color printing and avoiding the accumulation of positioning deviations;

● All color stations use the same central drum as the calibration reference, allowing precise adjustment of the contact pressure and position between the printing plate and the substrate. The register accuracy can reach ±0.1mm, meeting the fine overlay requirements of multi-color patterns;

● For stretchable substrates such as films and thin paper, the rigid support of the central drum reduces substrate deformation, ensuring consistency in multi-color register.

2. Substrate Compatibility: Covering Diverse Printing Needs

4/6/8-color flexographic printing often needs to handle diverse substrates, including plastic films (10–150μm), paper (20–400 gsm), and aluminum foil. The central drum structure enhances compatibility in the following ways:

●The central drum of a ci flexographic printing press typically has a diameter of ≥600-1200mm, providing a large substrate wrapping area and more uniform impression pressure. This enables adaptation to thick substrate printing and avoids local indentation issues;

●It reduces frictional contact between the substrate and multiple guide rollers, lowering the risk of scratches and wrinkles on thin substrates (e.g., PE films) and adapting to multi-color printing needs of different materials.

3. Production Efficiency: The "Speed-Boosting Key" for Multi-Color Printing

The efficiency of 4/6/8-color printing hinges on "synchronization" and "order change flexibility"—two aspects optimized by the central drum design:

● The circular arrangement of color stations allows the substrate to complete multi-color printing in a single pass, eliminating the need for sequential transfer between stations. The production speed can reach up to 300m/min, adapting to the efficient production of large-batch multi-color orders;

● During color changes, each color station can be adjusted independently around the central drum, without the need to re-calibrate the spacing between multiple rollers. This reduces order change time by 40%, making it more suitable for short-run, multi-batch multi-color printing needs.

4. Long-Term Operation: An "Optimization Solution" for Cost and Maintenance

From a long-term perspective, the central drum design optimizes cost-efficiency for the central impression flexo printing machine:

●The precise register effect effectively reduces printing waste rates. For every 10,000 meters of multi-color printing completed, it significantly cuts cost expenditures caused by substrate waste, controlling raw material loss at the source;

●Maintenance focuses on the core components of the central drum, requiring only regular inspections of bearings and reference calibration. Compared with equipment with multiple independent rollers, the annual maintenance cost is reduced by 25%.

● Video Introduction

III. Industry Adaptation: Alignment Between the Central Drum and Trends in Multi-Color Flexographic Printing

As the packaging industry upgrades its demands for "environmental friendliness, high definition, and high efficiency," 4/6/8-color flexo printing machines need to adapt to new consumables such as water-based inks and UV inks. The stable impression characteristics of the central drum better match the drying speed and printing effect of these new inks.

Meanwhile, the trend of "small-batch, multi-pattern" in daily chemical packaging has made the rapid order change advantage of the central drum even more valued.

● Printing Sample

Post time: Oct-11-2025