Against the backdrop of multiple challenges facing the current packaging and printing industry, enterprises need to seek solutions that can ensure stable operations and create sustainable value. The 4-color flexographic printing machine is precisely such a production tool with a solid foundation and significant value, and its application in the field of standard packaging demonstrates unique advantages in multiple aspects.

I. Guaranteed Continuous Operation of 4-Color Flexographic Printing Machines

Continuous production capacity is the core value of flexographic printing. Based on the mature web-fed printing process and combined with an efficient drying system, this type of equipment can maintain long-term stable operation, ensure the smooth execution of production plans, and provide reliable guarantee for enterprises’ order delivery.

Its flexible adaptability enables it to meet diversified business needs. The design concept of rapid job change allows enterprises to flexibly adjust production arrangements according to order conditions, effectively improving equipment utilization and creating more possibilities for business expansion.

The standardized operation process reduces the complexity of production management. By adopting the universal 4-color printing standard, a complete and standardized workflow is formed from substrate processing to finished product output, which reduces uncertainties in the production process and ensures the consistency of product quality.

The flexible space for equipment selection provides enterprises with more options:

●Stack flexo printing machines: Characterized by compact structure and easy operation, they are suitable for printing on various materials such as paperboard and films.

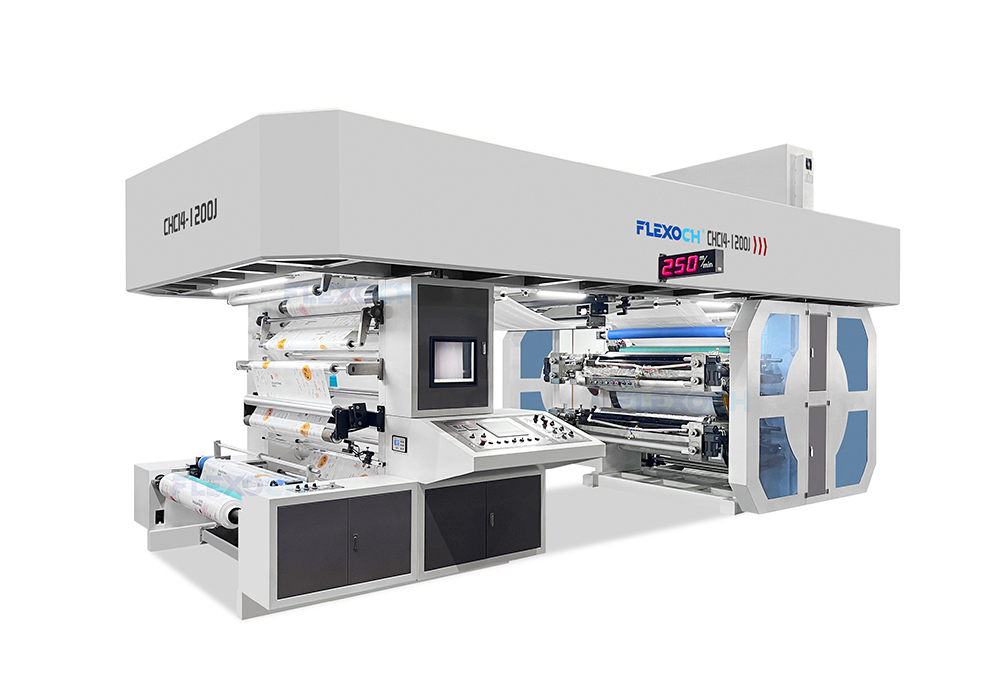

●Central Impression (CI) flexo printing machine: With excellent registration accuracy, they perform outstandingly in the printing of stretchable film materials.

●Gearless flexo printing press: Driven by independent servo motors for each color group, they achieve higher registration accuracy and intelligent operation, significantly improving printing quality and production efficiency.

These three mainstream machine types have their own characteristics and form a complete product matrix, which can fully meet the personalized production needs of enterprises of different scales.

II. Investment Value of 4 Colors flexo Printing machine

The comprehensive cost advantage is reflected in multiple dimensions. The cost-effectiveness of plate materials, the full utilization of inks, and the simplicity of equipment maintenance together form the foundation for cost control. Especially in long-run orders, the advantage of unit sheet printing cost is more prominent.

Investment rationality makes it a practical choice. Compared with large-scale equipment with complex functions, the investment in 4-color flexographic printing machine is more in line with the capital planning of most enterprises, and it can demonstrate investment benefits in a relatively short period, providing stable support for enterprise development.

Waste control capability directly affects profit levels. The low startup waste rate and the ability to quickly reach normal production status enable enterprises to obtain higher effective output in each order. This refined cost control is exactly what modern printing enterprises need.

● Machine Details

Printing Unit of Stack Printing Machine

Printing Unit of Stack Printing Machine

Printing Unit of Gearless Flexo Machine

III. Reliable Quality Performance

The color stability of flexographic printing machines ensures product consistency. Through a complete color management system and precise ink volume control, accurate color reproduction can be maintained across different batches and time periods, providing customers with stable and reliable product quality.

Material adaptability expands the business scope. Ideal printing results can be achieved on common paper materials as well as various plastic films. This wide applicability enables enterprises to better meet market demands and seize more business opportunities.

Durability enhances product value. The printed products have good wear resistance and scratch resistance, which can withstand the tests of subsequent processing and circulation links, ensuring that end-users receive intact products. This is not only a responsibility to customers but also a maintenance of the enterprise’s reputation.

IV. Strong Support for Sustainable Development

The environmental-friendly features of 4 color flexo printing machine are in line with industry development trends. The low-emission and low-energy-consumption production method not only meets current environmental protection requirements but also lays a foundation for the long-term development of enterprises. This eco-friendly production method is becoming a new standard in the industry.

Conclusion

The value of four color flexo printing machine in the field of standard packaging printing is not only reflected in their stable production performance and reliable quality output but also in providing a steady development path for printing enterprises. It helps enterprises establish a stable and reliable production system, achieve refined cost control, and fully prepare for future market changes.

● Printing Sample

Post time: Oct-22-2025