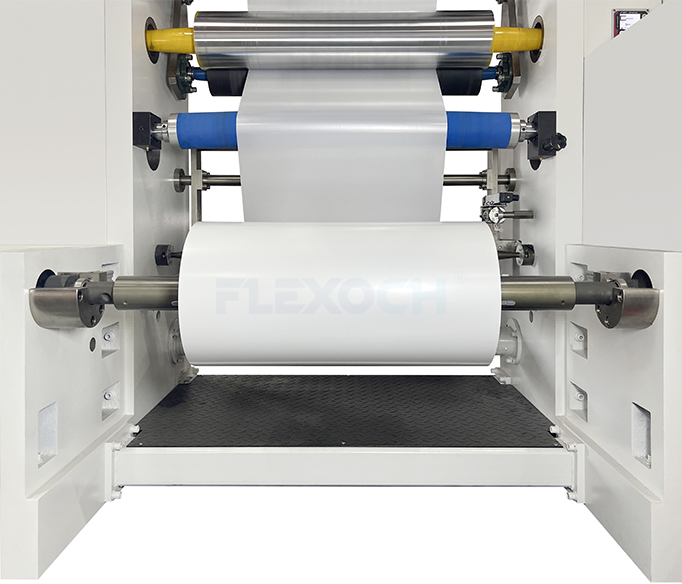

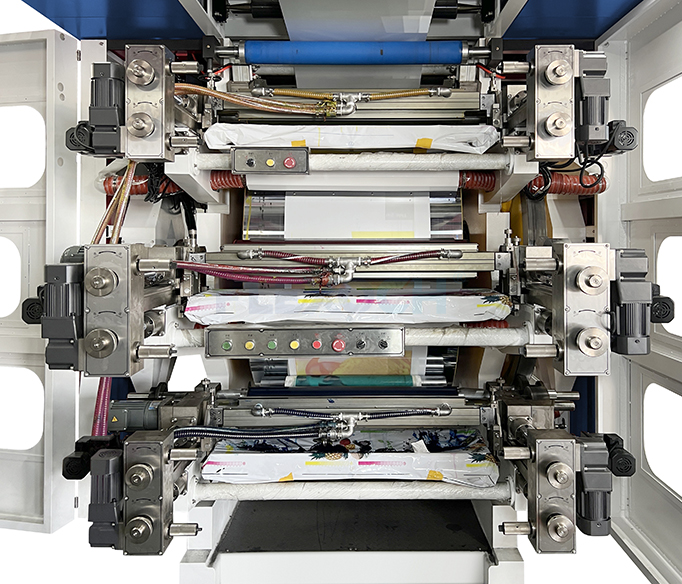

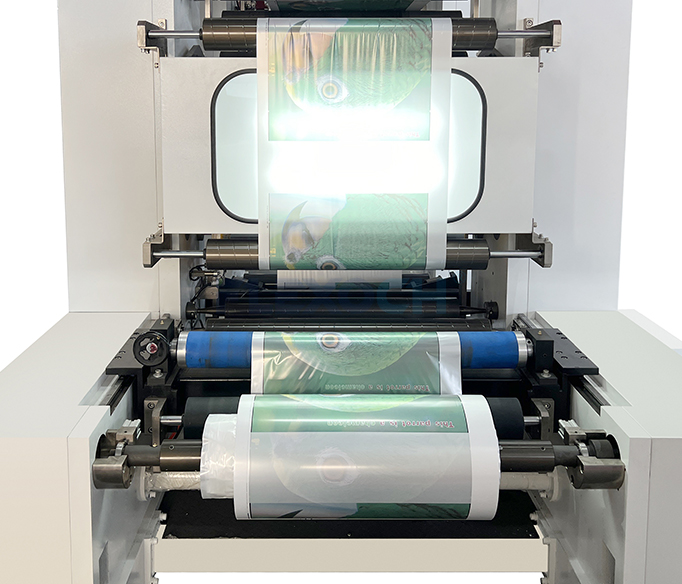

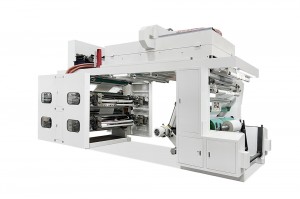

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for High Quality Automatic High Speed 4 6 8 Colors Flexo Printing Machine for LDPE/CPP/ BOPP/LDPE, We welcome new and old customers from all walks of life to contact us for future business relationships and achieve mutual success!

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for , We expect to provide goods and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

|

model

|

CHCI6-600E-S

|

CHCI6-800E-S

|

CHCI6-1000E-S

|

CHCI6-1200E-S

|

|

Max.Web Width

|

700mm

|

900mm

|

1100mm

|

1300mm

|

|

Max.Printing Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max.Machine Speed

|

350m/min

|

|

Max. Printing Speed

|

300m/min

|

|

Max.Unwind/Rewind Dia.

|

Φ800mm /Φ1000mm/Φ1200mm |

|

Drive Type

|

Central drum with Gear drive |

| Photopolymer Plate |

To be specified |

|

Ink

|

Water base ink olvent ink |

|

Printing Length (repeat)

|

350mm-900mm |

|

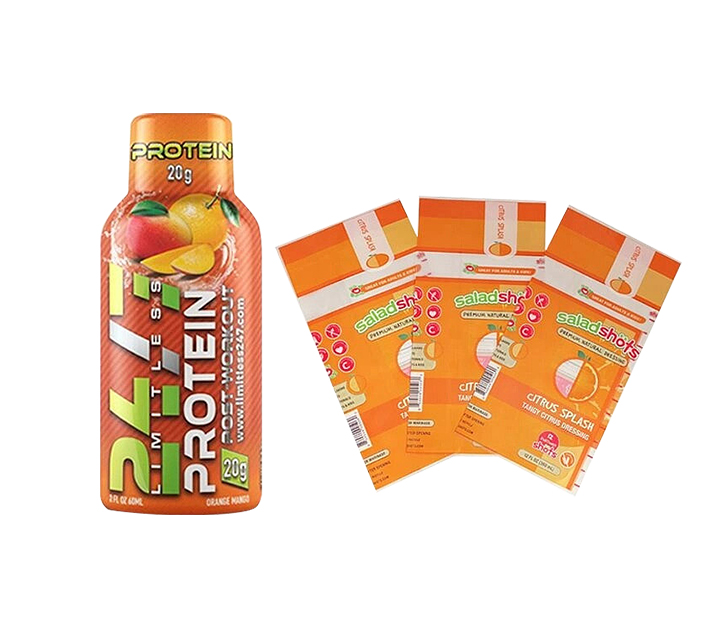

Range Of Substrates

|

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

|

Electrical Supply

|

Voltage 380V.50 HZ.3PH or to be specified |

We strive for excellence, service the customers”, hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for High Quality Automatic High Quality Automatic High Speed 4 6 8 Colors Flexo Printing Machine for LDPE/CPP/ BOPP/LDPE, We welcome new and old customers from all walks of life to contact us for future business relationships and achieve mutual success!

High Quality CI Flexo Printing Machine and 6 Color Flexo Printing Machine, We expect to provide goods and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.