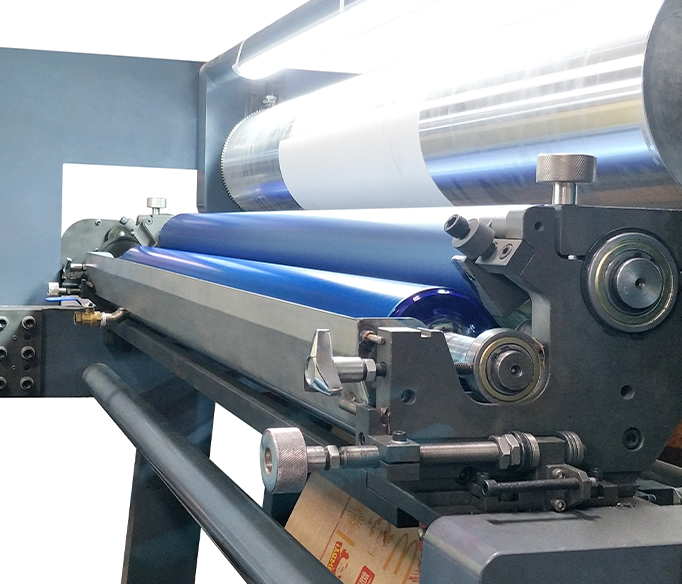

To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Good Quality HDPE LDPE LLDPE Film paper non woven Flexo printing Machine with inline Flexo Printing machine, “Change to the far better!” is our slogan, which means “A better globe is before us, so let’s love it!” Change to the much better! Are you all set?

To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for , Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers’ satisfaction and achieve win-win situation .

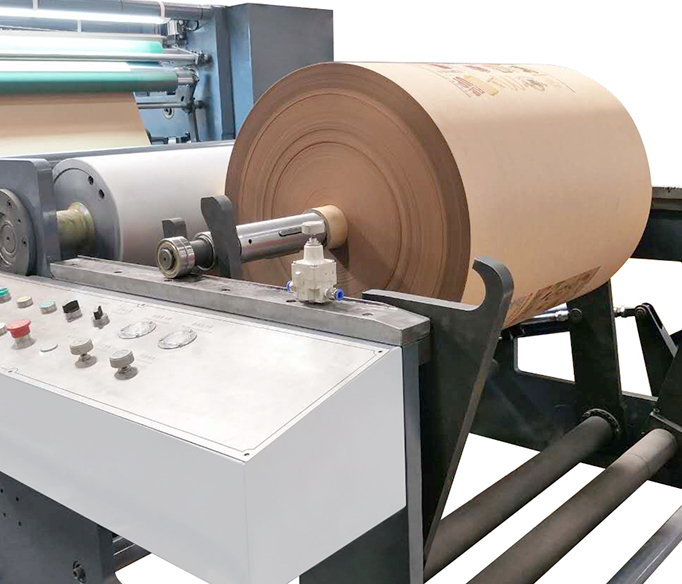

| Model |

CH6-1200A |

| Maximum winding and unwinding diameter |

ф1524 |

| Inner diameter of paper core |

3″OR 6″ |

| Maximum paper width |

1220MM |

| Repeat length of printing plate |

380-1200mm |

| Plate thickness |

1.7mm or to be specified |

| Thickness of plate mounting tape |

0.38mm or to be specified |

| Registration accuracy |

±0.12mm |

| Printing paper weight |

40-140g/m2 |

| Tension control range |

10-50kg |

| Maximum printing speed |

100m/min |

| Maximum machine speed |

150m/min |

To continually enhance the management technique by virtue of your rule of “sincerely, great faith and high-quality are the base of company development”, we widely absorb the essence of similar merchandise internationally, and continuously build new merchandise to meet the demands of customers for Good Quality HDPE LDPE LLDPE Film Extruding Machine with Flexo Printing Inline, “Change to the far better!” is our slogan, which means “A better globe is before us, so let’s love it!” Change to the much better! Are you all set?

Good Quality printing flexo machine and flexo presses, Besides there are also experienced production and management , advanced production equipment to assure our quality and delivery time , our company pursues the principle of good faith, high-quality and high-efficiency. We guarantee that our company will try our best to reduce customer purchase cost, shorten the period of purchase, stable solutions quality, increase customers’ satisfaction and achieve win-win situation .