Our personnel are always in the spirit of “continuous improvement and excellence”, and with the superior quality products, favorable price and good after-sales services, we try to win every customer’s trust for Factory Price For Stack Flexo Printing Machine for BOPP non woven Film Roll to roll, You should send us your specifications and requirements, or feel totally free to speak to us with any questions or inquiries that you may have.

Our personnel are always in the spirit of “continuous improvement and excellence”, and with the superior quality products, favorable price and good after-sales services, we try to win every customer’s trust for , We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

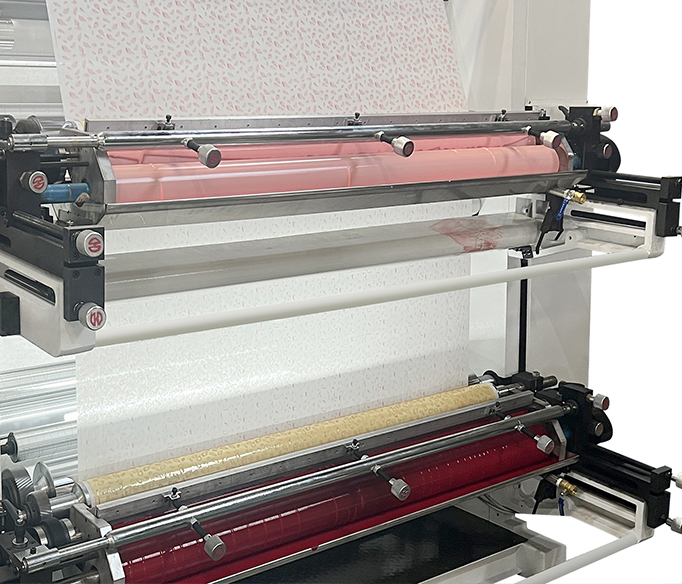

| Model |

CH4-600B-Z |

CH4-800B-Z |

CH4-1000B-Z |

CH4-1200B-Z |

| Max.Web Width |

600mm |

850mm |

1050mm |

1250mm |

| Max.Printing Width |

560mm |

760mm |

960mm |

1160mm |

| Max.Machine Speed |

120m/min |

| Max.Printing Speed |

100m/min |

| Max.Unwind/Rewind Dia. |

Φ1200mm/Φ1500mm |

| Drive Type |

Synchronous belt drive |

| Photopolymer Plate |

To be specified |

| Ink |

Water base ink or solvent ink |

| Printing Length (repeat) |

300mm-1300mm |

| Range Of Substrates |

Paper、Non Woven、Paper Cup |

| Electrical Supply |

Voltage 380V.50 HZ.3PH or to be specified |

Our personnel are always in the spirit of “continuous improvement and excellence”, and with the superior quality products, favorable price and good after-sales services, we try to win every customer’s trust for Factory Price For Stack Flexo Printing Machine for BOPP non woven Film Roll to roll , You should send us your specifications and requirements, or feel totally free to speak to us with any questions or inquiries that you may have.

Factory Price For Roll to roll non woven Printing Machine and Flexo Printing Machine Press, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.