- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

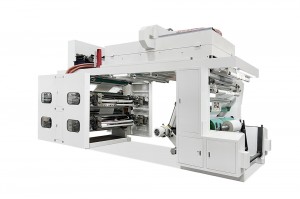

Factory making Flexo Printing Machine 4 6 8 Color Roll Flexographic Printer High Speed Label Graphic PP Non Woven Bag Printing machine 380V 4 Color

Factory making Flexo Printing Machine 4 6 8 Color Roll Flexographic Printer High Speed Label Graphic PP Non Woven Bag Printing machine 380V 4 Color

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for Factory making Flexo Printing Machine 4 6 8 Color Roll Flexographic Printer High Speed Label Graphic PP Non Woven Bag Printing machine 380V 4 Color, We’ve been now searching ahead to even increased cooperation with abroad consumers determined by mutual positive aspects. In case you are intrigued in almost any of our solutions, remember to experience totally free to speak to us for additional facts.

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for , Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

Product Video

Machine Features

Characteristic:

1. Take it easy, accurate color, long life.

2. The use of motors, variable frequency speed control, saving electricity, running small fluctuations.

3. Off printing roll automatic stop the ink-running motor, and up-printing roll automatic start running the ink.

4. The use of special diagonal-tooth gear, print size is accurate.

5. There are two sets of heating devices, including central heating and constant temperature control system for packet control.

6. Low-roller special steel processing, and special process, and plating thickness of 0.1mm protective layer of hard chromium.

7. Alloy roll with hard oxidation, treating by dynamic balance, static balanced.

8. With a cold wind bellows, and can effectively prevent produce with ink adhesion after printing.

9. The Print produce are clear and good arrangement quality.

Production technology:

Single Unwind system –Auto tension control –Auto EPC Web guide–Printing Unit–Dry system after printing–Surface rewinder

Main parameter:

| Model | CH-600N | CH-800N | CH-1000N | CH-1200N | CH-1400N | CH-1600N |

| Max. Material width |

600mm |

800mm |

1000mm |

1200mm |

1400mm |

1600mm |

| Max. Printing width |

550mm |

750mm |

950mm |

1150mm |

1350mm |

1550mm |

| Printing material | PP WOVEN,Paper,Non woven.etc | |||||

| Printing color | 4 color (4+0,3+1,2+2),6 colors (6+0,5+1,4+2,3+3),8 colors (9+0,7+1,6+2,5+3,4+4) | |||||

| Printing length | 300mm-950mm ( If you have different printing length which you want, pls let me know soon) | |||||

| Printing plate lifting system | Hydraulic press control | |||||

1.1) Unwind Unit

| Unwind way | Auto loading . Auto tension controller with Magnetic powder |

| Alarm device when off material | Automatic keep tension when machine stop .avoid material loose |

| Tension precision | ±0.3kg |

| EPC system for unwind | Edge position control 1 pcs |

| Unwind way | Air shaft 3” 1 PCS |

1.2) Traction Unit

| Traction type | Chrome roller |

| Traction unit | 2 unit. unwind traction and rewind traction |

| Bearing | HRB |

| Single bearing | ASNU. Germany |

1.3) Printing Unit

| Driving type | Belt drive |

| Ink | Water base or solvent Ink |

| Printing plate | Sensitive resin plate or rubber plate |

| Constitution of printing | Anilox roller. Open Doctor blade. Printing cylinder. Printing plate |

| Anilox roller | Ceramic anilox roller |

| Printing pressure | Mechanical adjust |

| Color register type | By manual (Automatic print after beforehand overprint. when start machine.no need register color again ) |

| Printing plate lifting system | Auto hydraulic cylinder control roll up and down |

1.4) Drying Unit

| Dry way | Electrical heating |

| Blower | Domestic |

| Power of Heating | 45 kw |

1.5) Electrical Unit

| Main motor | Taiwan delta |

| Electronic control system | Operation control panel 1 pcs |

1.6) Rewind Unit

| Max. Diameter | Φ1000mm |

| Rewind way | Superficial curl |

| Tension control system | Dancing roller. Speed model closed-loop control. tension closed-loop |

| Rewind material holder | Air shaft 2 pcs |

| Rewind motor | Taiwan |

| Rewind Paper core | Φ76mm ( Inner diameter ) |

Machine Main Parts brand

| Contactor | Schneider | LCI-E2510 | 8pcs |

| Breaker | Schneider | 100A40A20A | 1pcs3pcs1pcs |

| Counter | CHINT | JC725 | 1pcs |

| Urgent Stop Switch | Schneider | ZB2-BE102C | 2pcs |

| Revolve Button Switch | WENZHOU | LAY16 | 2pcs |

| Mini Relay | Schneider | CKC220VAC | 3pcs |

| Button Switch | Schneider | / | |

| Temperature Meter | Schneider | XMTD-9131 | 2pcs |

| Hint Light | CHINA | / | |

| Electric-thermal Couple | Schneider | MT-2M | 2pcs |

| Frequency converter | Inovance. China | H-3624MT | 1pcs |

| Auto Tension Control | CHINA | B-600 | 2pcs |

| Main Motor | China | H-3624MT | 1pcs |

| 14 Edge Position Control | CHINA | 1pcs | |

| 15 Touch screen | CHINA | MCGS | 1 pcs |

Printing Sample

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for Factory making Flexo Printing Machine 4 6 8 Color Roll Flexographic Printer High Speed Label Graphic PP Non Woven Bag Printing machine 380V 4 Color, We’ve been now searching ahead to even increased cooperation with abroad consumers determined by mutual positive aspects. In case you are intrigued in almost any of our solutions, remember to experience totally free to speak to us for additional facts.

To become the stage of realizing dreams of our employees! To build a happier, additional united and additional experienced team! To reach a mutual gain of our clients, suppliers, the society and ourselves for Factory making Flexo Printing Machine 4 6 8 Color Roll Flexographic Printer High Speed Label Graphic PP Non Woven Bag Printing machine 380V 4 Color, We’ve been now searching ahead to even increased cooperation with abroad consumers determined by mutual positive aspects. In case you are intrigued in almost any of our solutions, remember to experience totally free to speak to us for additional facts.

Factory making stack type flexographic printing machine and flexographic presses, Our company, is always regarding quality as company’ s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.