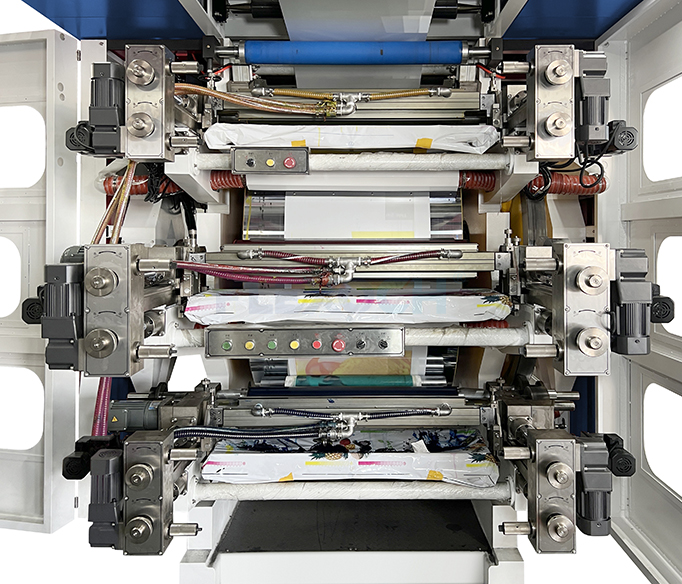

1. The ceramic anilox roller is used to accurately control the amount of ink, so when printing large solid color blocks in flexographic printing, only about 1.2g of ink per square meter is required without affecting color saturation.

2. Due to the relationship between the flexographic printing structure, ink, and amount of ink, it does not require too much heat to completely dry the printed job.

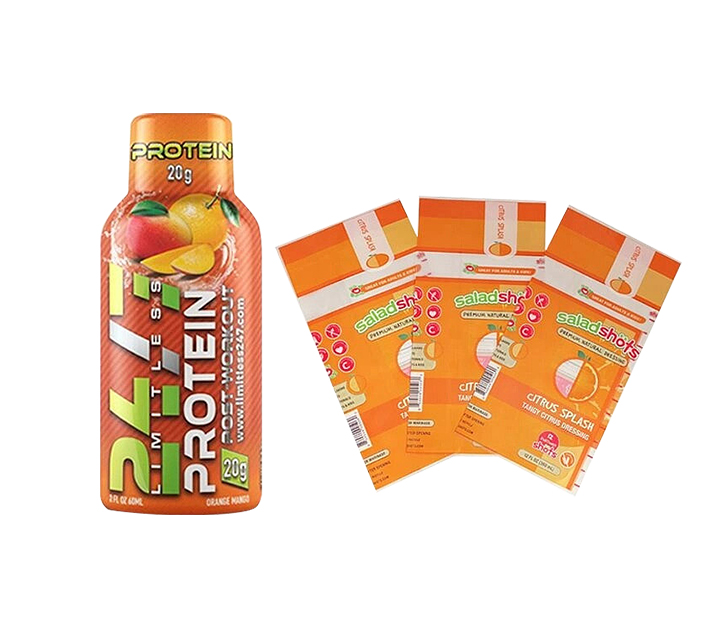

3. In addition to the advantages of high overprinting accuracy and fast speed. It actually has a very big advantage when printing large-area color blocks (solid).