With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for Discount Price Roll to Roll 2 4 6 8 Color Automatic Printing Machine for BOPP Film Plastic Flexographic Printing Machinery Sale Cheap Price, Since the manufacturing unit founded, we have now committed into the progress of new goods. Along with the social and economic pace, we’ll continue to carry forward the spirit of “high excellent, efficiency, innovation, integrity”, and stay with the operating principle of “credit initially, customer 1st, good quality excellent”. We’ll produce a excellent foreseeable future in hair output with our companions.

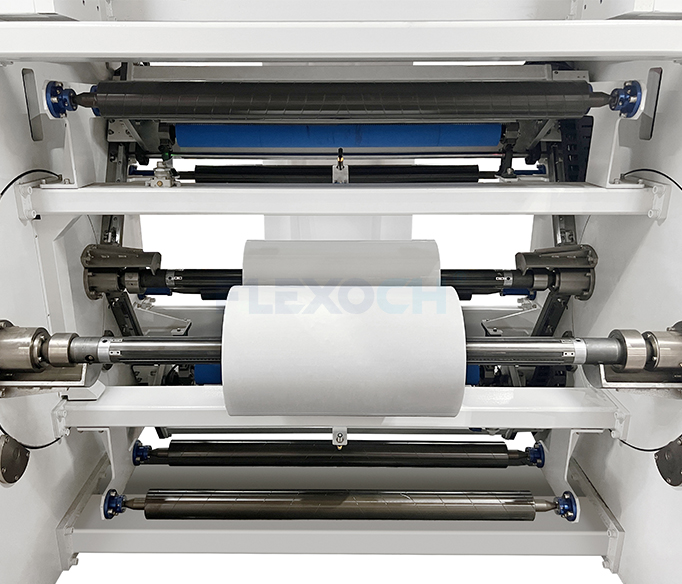

With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for 4 6 8 10 Color Printing Machine and 4 6 8 colour CI Flexographic Printing Machine, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!

|

model

|

CHCI8-600E-S

|

CHCI8-800E-S

|

CHCI8-1000E-S

|

CHCI8-1200E-S

|

|

Max.Web Width

|

700mm

|

900mm

|

1100mm

|

1300mm

|

|

Max.Printing Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max.Machine Speed

|

350m/min

|

|

Max. Printing Speed

|

300m/min

|

|

Max.Unwind/Rewind Dia.

|

Φ800mm /Φ1000mm/Φ1200mm |

|

Drive Type

|

Central drum with Gear drive |

| Photopolymer Plate |

To be specified |

|

Ink

|

Water base ink olvent ink |

|

Printing Length (repeat)

|

350mm-900mm |

|

Range Of Substrates

|

LDPE, LLDPE, HDPE, BOPP, CPP, OPP, PET, Nylon, |

|

Electrical Supply

|

Voltage 380V.50 HZ.3PH or to be specified |

With our exceptional administration, robust technical capability and strict high-quality control procedure, we carry on to provide our consumers with dependable high-quality, reasonable selling prices and superb providers. We aim at becoming amongst your most responsible partners and earning your pleasure for DDiscount Price Roll to Roll 2 4 6 8 Color Automatic Printing Machine for BOPP Film Plastic Flexographic Printing Machinery Sale Cheap Price, Since the manufacturing unit founded, we have now committed into the progress of new goods. Along with the social and economic pace, we’ll continue to carry forward the spirit of “high excellent, efficiency, innovation, integrity”, and stay with the operating principle of “credit initially, customer 1st, good quality excellent”. We’ll produce a excellent foreseeable future in hair output with our companions.

Discount Price 4 6 8 10 Color Printing Machine and 4 6 8 colour CI Flexographic Printing Machine, Due to our strict pursues in quality, and after-sale service, our product gets more and more popular around the world. Many clients came to visit our factory and place orders. And there are also many foreign friends who came for sight seeing, or entrust us to buy other stuff for them. You are most welcome to come to China, to our city and to our factory!