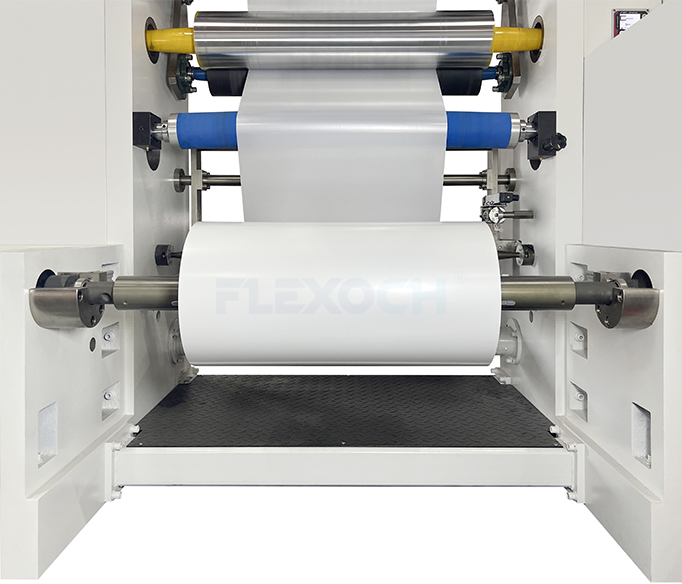

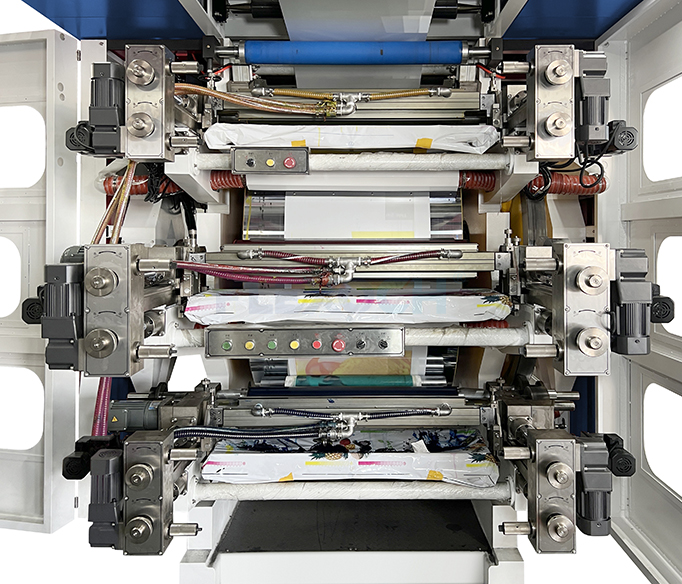

“Based on domestic market and expand overseas business” is our development strategy for China Factory for High Speed 4 6 8 Color Central Impression Paper Plastic Flexo Printing Machine, We are able to do your tailored get to fulfill your own satisfactory! Our organization sets up several departments, including manufacturing department, sales department, high quality control department and sevice center, etc.

“Based on domestic market and expand overseas business” is our development strategy for Flexographic Printing Machine and BOPP Flexo Printing Machine, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We have Updated our catalog, which introduces our organization. n detail and covers the primary products we offer at existing, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

|

model

|

CHCI6-600E-S

|

CHCI6-800E-S

|

CHCI6-1000E-S

|

CHCI6-1200E-S

|

|

Max.Web Width

|

700mm

|

900mm

|

1100mm

|

1300mm

|

|

Max.Printing Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max.Machine Speed

|

350m/min

|

|

Max. Printing Speed

|

300m/min

|

|

Max.Unwind/Rewind Dia.

|

Φ800mm /Φ1000mm/Φ1200mm |

|

Drive Type

|

Central drum with Gear drive |

| Photopolymer Plate |

To be specified |

|

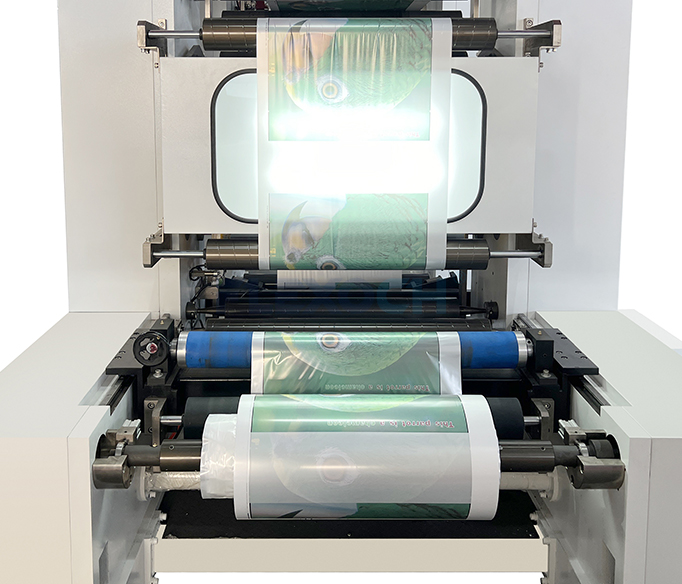

Ink

|

Water base ink olvent ink |

|

Printing Length (repeat)

|

350mm-900mm |

|

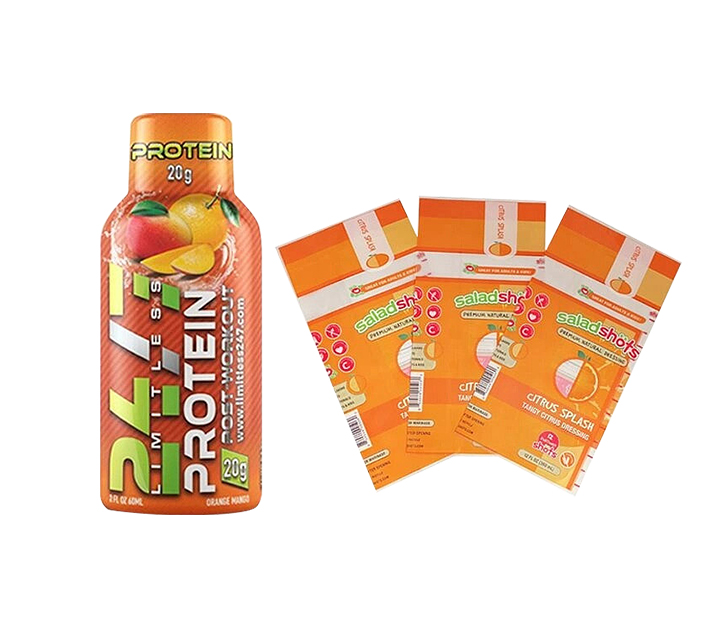

Range Of Substrates

|

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

|

Electrical Supply

|

Voltage 380V.50 HZ.3PH or to be specified |

“Based on domestic market and expand overseas business” is our development strategy for China Factory for High Speed 4 6 8 Color Central Impression Paper Plastic Flexo Printing Machine, We are able to do your tailored get to fulfill your own satisfactory! Our organization sets up several departments, including manufacturing department, sales department, high quality control department and sevice center, etc.

China Factory for Flexographic Printing Machine and BOPP Flexo Printing Machine, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We have Updated our catalog, which introduces our organization. n detail and covers the primary products we offer at existing, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.