abide by the contract”, conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients’ gratification for Bottom price High Quality Stack Flexo Paper Cups Paper Bags Printing Machine Label Printing Machine Paper Printing Press, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

abide by the contract”, conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients’ gratification for , To work with an excellent products and solutions manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

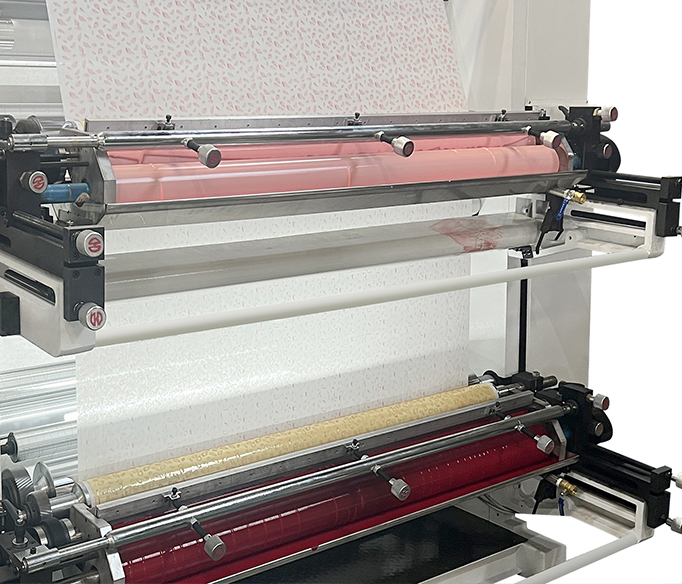

| Model |

CH4-600B-Z |

CH4-800B-Z |

CH4-1000B-Z |

CH4-1200B-Z |

| Max.Web Width |

600mm |

850mm |

1050mm |

1250mm |

| Max.Printing Width |

560mm |

760mm |

960mm |

1160mm |

| Max.Machine Speed |

120m/min |

| Max.Printing Speed |

100m/min |

| Max.Unwind/Rewind Dia. |

Φ1200mm/Φ1500mm |

| Drive Type |

Synchronous belt drive |

| Photopolymer Plate |

To be specified |

| Ink |

Water base ink or solvent ink |

| Printing Length (repeat) |

300mm-1300mm |

| Range Of Substrates |

Paper、Non Woven、Paper Cup |

| Electrical Supply |

Voltage 380V.50 HZ.3PH or to be specified |

abide by the contract”, conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients’ gratification for Bottom price High Quality Stack Flexo Paper Cups Paper Bags Printing Machine Label Printing Machine Paper Printing Press, The continual availability of high grade solutions in combination with our excellent pre- and after-sales services ensures strong competitiveness in an increasingly globalized market place.

Bottom price Flexographic Printing Press and Flexo Printing Press, To work with an excellent products and solutions manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.