- FUJIAN CHANGHONG PRINTING MACHINE CO., LTD

- sale8@chprintingmachine.com

- +86 18150207107

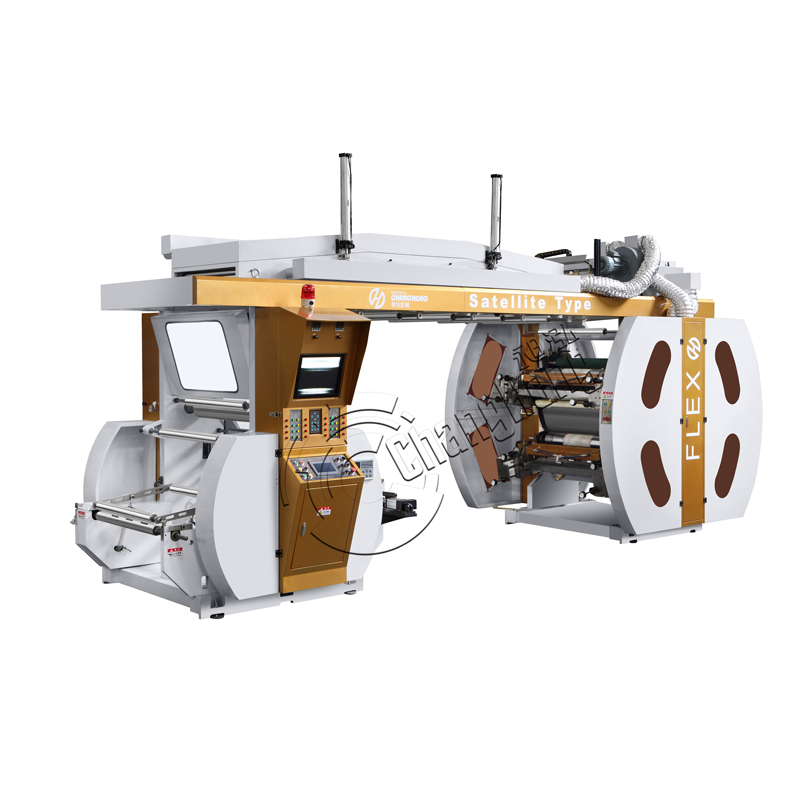

Best High Quality Flexographic Printing Machine 8 Colors Factory – Plastic film/Paper/Non woven/Gearless CI flexo printing press – Changhong Printing

Best High Quality Flexographic Printing Machine 8 Colors Factory – Plastic film/Paper/Non woven/Gearless CI flexo printing press – Changhong Printing

Best High Quality Flexographic Printing Machine 8 Colors Factory – Plastic film/Paper/Non woven/Gearless CI flexo printing press – Changhong Printing Detail:

“Flexography (flexography), also often referred to as flexographic printing, is a full-servo flexographic printing press that uses a flexographic plate to transfer ink through an anilox roller, and abandons the traditional mechanical gear transmission. The servo is used to control the phase of each color printing roller, which not only improves the speed but also ensures the accuracy.”

| TECHNICAL SPECIFICATIONS | ||||

| Model | CHCI6-600F | CHCI6-800F | CHCI6-1000F | CHCI6-1200F |

| Max. Web Width | 650mm | 850mm | 1050mm | 1250mm |

| Max. Printing Width | 550mm | 750mm | 950mm | 1150mm |

| Max. Machine Speed | 500m/min | |||

| Printing Speed | 450m/min | |||

| Max. Unwind/Rewind Dia. | φ800mm (Special size can be customized) | |||

| Drive Type | Gearless full servo drive | |||

| Plate thickness | Photopolymer plate 1.7mm or 1.14mm (or to be specified) | |||

| Ink | Water base ink or solvent ink | |||

| Printing length (repeat) | 300mm-800mm (Special size can be customized) | |||

| Range Of Substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Electrical supply | Voltage 380V. 50 HZ.3PH or to be specified | |||

Double station Unwinding Unit→Traction Unit→EPC→Printing Unit→Centralized heating→Traction&cooling→Double station winding

Double station unwinding

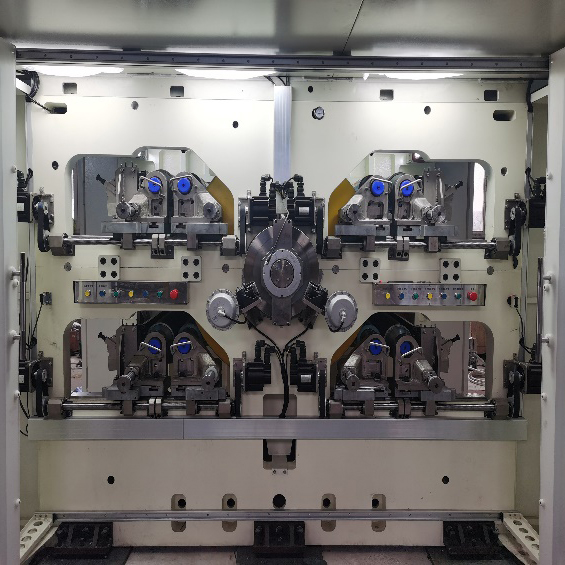

Full servo Printing system

Pre registration function (Automatic Registration)

Production menu memory function

Start up and shut down automatic clutch pressure function

Automatic pressure adjustment function in the process of printing speed up

Chamber doctor blade quantitative ink supply system

temperature control and centralized drying after printing

EPC before printing

It has cooling function after printing

Double station winding.

Gearless CI flexo printing press has a wide range of application materials and is highly adaptable to various materials, such as transparent film, non-woven fabric, paper, etc.

.jpg)

Product detail pictures:

Related Product Guide:

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth unification, determination, tolerance for Best High Quality Flexographic Printing Machine 8 Colors Factory – Plastic film/Paper/Non woven/Gearless CI flexo printing press – Changhong Printing , The product will supply to all over the world, such as: Estonia, Spain, Toronto, Now, with the development of internet, and the trend of internationalization, we have decided to extend business to overseas market. With the propose of bringing more profits to oversea customers by providing directly abroad. So we have changed our mind, from home to abroad, hope to give our customers more profit, and looking forward to more chance to make business.