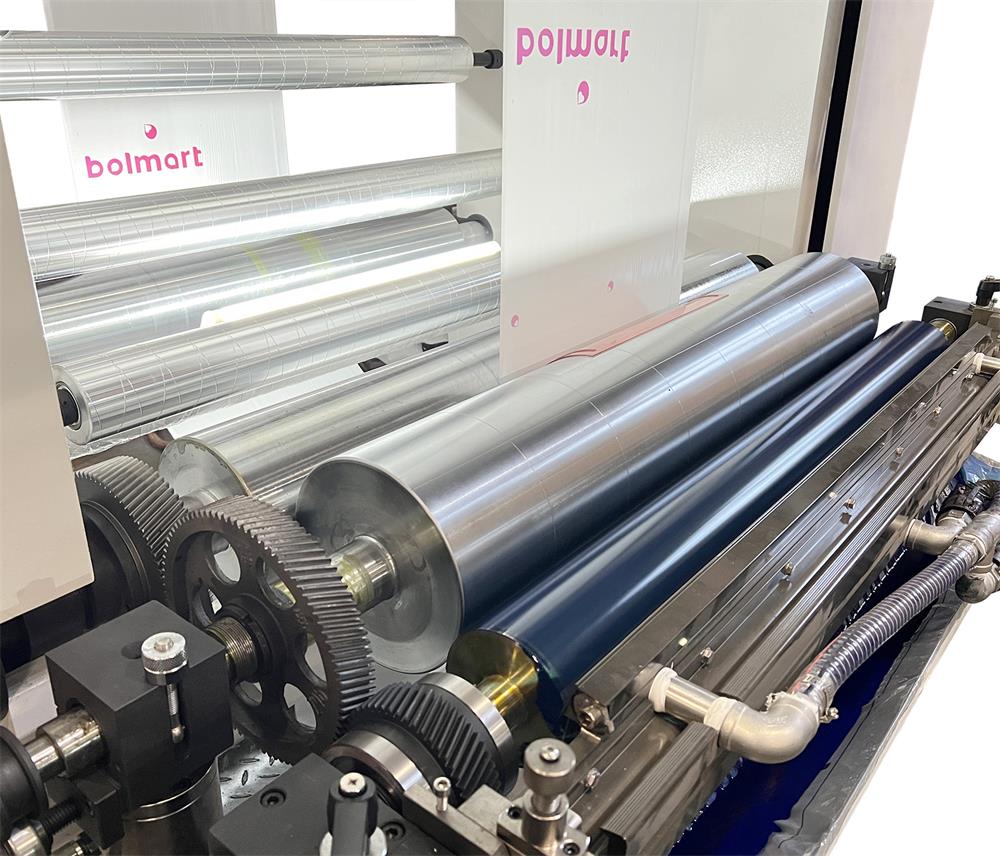

We pursue the administration tenet of “Quality is remarkable, Services is supreme, Status is first”, and will sincerely create and share success with all customers for 2025 Good Quality High-Performance Six-Color stack Flexo Printing Machine for plastic films BOPP/LDPE/CPP, Our goods are widely used in many industrial fields. Our Corporation Services Division in good faith for that purpose of the quality of survival. All for customer company.

We pursue the administration tenet of “Quality is remarkable, Services is supreme, Status is first”, and will sincerely create and share success with all customers for , We have now to continue to uphold the “quality, comprehensive, efficient” business philosophy of “honest, responsible, innovative”spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.

| Model |

CH6-600B-S |

CH6-800B-S |

CH6-1000B-S |

CH6-1200B-S |

| Max. Web Width |

650mm |

850mm |

1050mm |

1250mm |

| Max. Printing Width |

560mm |

760mm |

960mm |

1160mm |

| Max. Machine Speed |

120m/min |

| Max. Printing Speed |

100m/min |

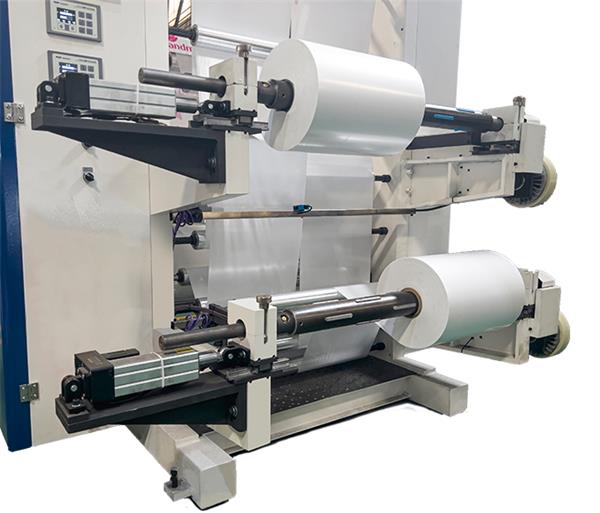

| Max. Unwind/Rewind Dia. |

Φ600mm |

| Drive Type |

Synchronous belt drive |

| Photopolymer Plate |

To be specified |

| Ink |

Water base ink olvent ink |

| Printing Length (repeat) |

300mm-1300mm |

| Range Of Substrates |

LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, |

| Electrical Supply |

Voltage 380V.50 HZ.3PH or to be specified |

We pursue the administration tenet of “Quality is remarkable, Services is supreme, Status is first”, and will sincerely create and share success with all customers for 2025 Good Quality High-Performance Six-Color stack Flexo Printing Machine for plastic films BOPP/LDPE/CPP, Our goods are widely used in many industrial fields. Our Corporation Services Division in good faith for that purpose of the quality of survival. All for customer company.

2025 Good Quality Pad central impression flexo press and flexographic printing press, We have now to continue to uphold the “quality, comprehensive, efficient” business philosophy of “honest, responsible, innovative”spirit of service, abide by the contract and abide by reputation, first-class goods and improve service welcome overseas customers patrons.