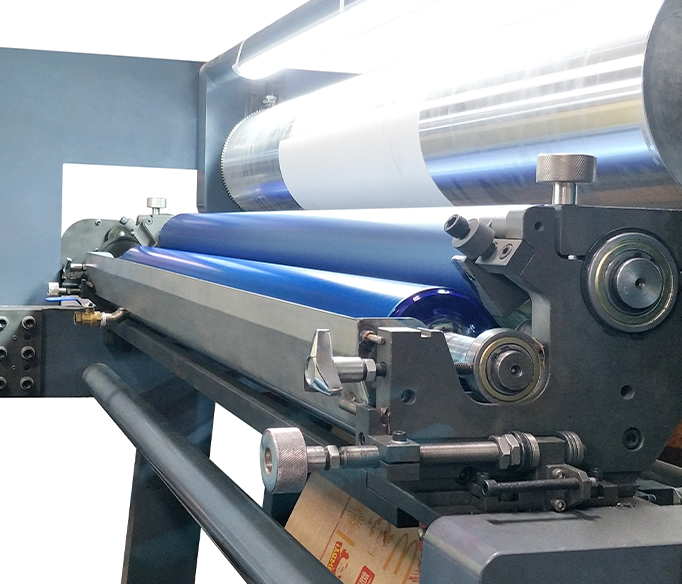

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for 100% Original Factory inline Flexo Printing Machine for paper cup, It is our great honor to fulfill your needs.We sincerely hope we will cooperate along with you inside the close to foreseeable future.

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for , To create more creative items, maintain high-quality products and solutions and update not only our items but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we supply and to grow stronger together. To be the real winner, starts here!

| Model |

CH6-1200A |

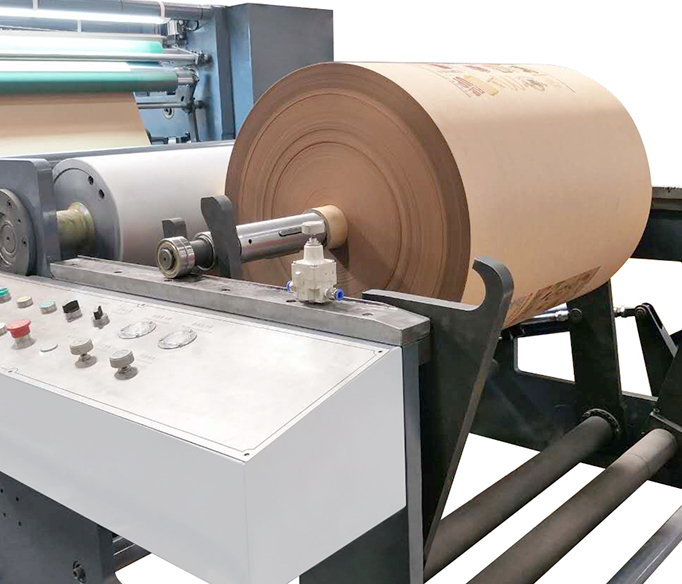

| Maximum winding and unwinding diameter |

ф1524 |

| Inner diameter of paper core |

3″OR 6″ |

| Maximum paper width |

1220MM |

| Repeat length of printing plate |

380-1200mm |

| Plate thickness |

1.7mm or to be specified |

| Thickness of plate mounting tape |

0.38mm or to be specified |

| Registration accuracy |

±0.12mm |

| Printing paper weight |

40-140g/m2 |

| Tension control range |

10-50kg |

| Maximum printing speed |

100m/min |

| Maximum machine speed |

150m/min |

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for 100% Original Factory inline Flexo Printing Machine for paper cup, It is our great honor to fulfill your needs.We sincerely hope we will cooperate along with you inside the close to foreseeable future.

100% Original Factory Flexo Printing Machine and Four Colour flexo printing machine, To create more creative items, maintain high-quality products and solutions and update not only our items but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we supply and to grow stronger together. To be the real winner, starts here!